Cook and Chill system C&C250

Cook and chill cooker C&C250:

The cook and chill system machine with tilting discharging mechanism designed for the cooking of fruit, vegetables, meat, seafood and another sectors for boiling or blanching materials, like:

- mushrooms

- rice

- sea products

- meat

- pasta

Thanks to the intensive stirring with the hydrodynamic mixer, cook and chill cooker is applicable for the heat processing of materials with a soft exterior, like mussels.

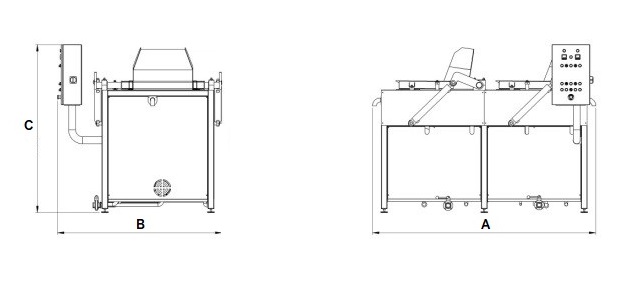

Cook and chill cooker design

The construction of this cook and chilll system machine comprises of an operating tank with direct steam heating, tilting perforated basket, a hydrodynamic stirring system and a water circulation and filtration mechanism.

Easy discharging with minimum water losses. A lifting perforated basket with pneumatic ensures a comfortable discharge of the product. Furthermore, a tilting system is also supplied to shake the basket in an elevated position, ensuring the maximal possible elimination of water from the final material.

Complete manufacturing phase – From Cleansing To Cooling – In one machine

The interchangeable form enables a treatment mechanism which ensures the optimum heat processing of any product in the these modes: blanching – cooking – pre-cooling – cooling. Available is also an optional cleaning of materials in cool or hot water if needed.

A modern hydrodynamic stirrer, installed in the C&C cooking equipment, will boost the heat distribution between the material and the heating mechanism, leading to a decline in the processing time and an even processing of the material, prevention from adhering and being destroyed.

The optimal volume rate of the material to water differs depending on the material. Following finishing of the boiling process, the staff raises the perforated basket, fitted with a pneumatic, hydraulic or mechanical drive (depends on the capacity and client’s requirements). The surplus of water goes back into the cooking tank. The basket performs shaking. With an abrubt incline, the material is discharged in the collecting or chilling tank.

Cook and Chill system machine with Automated Control Mechanism

The control mechanism decreases the staff involvement. The controlling of parameters like water temperature at each step, the cooking time and the water level are determined automatically for each material.

Cook and chill system - Benefits:

- Saving money - quick heating, the maximal distribution of heat into the material, substantially reducing the processing time.

- Highest quality of the final material – an even heat processing, the material doesnt adhere and the exterior doesnt get destroyed.

- Easy operation – the construction of the cooking equipment allows for comfortable loading of the material. Available is also a choice for the machine to be equipped with tilting lifting mechanism. Simple discharging of the product is executed using a lifting tilting perforated basket.

- Interchangeable structure – machine may be equipped with extra parts (pre-cleaning, blanching, boiling, pre-cooling, or cooling).

- High quality operation

- Modern filter mechanism – efficiently eliminates tiny pieces of the material and enables the water usage for longer period of time.

- Various sources of heating – the equipment may be adjusted to client's requirements with choices for steam or electric heating.

|

Model: C&C |

250 |

|

Geom. volume, L |

250 |

|

Basket volume, L |

175 |

For more information please click the link Cook and Chill system 250