Conveyors

We provide the following types of conveyors.

For more information about our product contact our sales department: This email address is being protected from spambots. You need JavaScript enabled to view it.

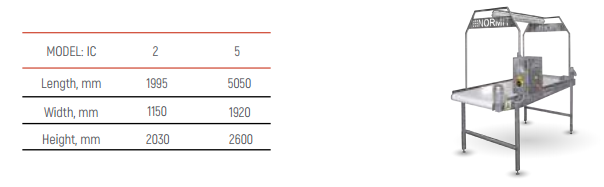

INSPECTION CONVEYOR IC Inspection conveyor is designed for monitoring and manual removal of the defective products. It can be integrated into various parts of the production line. The basic construction of the inspection conveyor comprises a conveyor belt made of a food grade PVC, of a white color for an optimal contrast with the product, the lighting system along the entire length of the conveyor, and the side margins for a rapid removal of the defective product. The speed of movement of the conveyor belt is adjustable with the frequency converter.

THE DC STACKING CONVEYOR serves for storing products entering or leaving the process line. The PVC belt slowly moves the product, which is deposited/spread manually on the belt.

CONVEYOR FOR CAN CFC is mostly used as a part of the container washing line. It is used to transport containers, into a further production process.

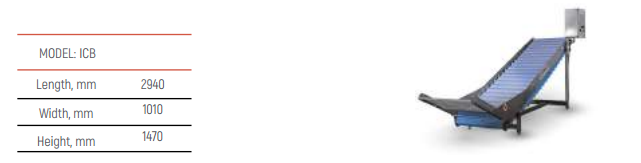

INCLINED VIBRATING CONVEYOR ICB is used to transport products to higher places. A sieve with a vibration capability is placed at the bottom for the removal of smaller unnecessary particles that are undesirable in the next working process. The conveyor belt is modular.

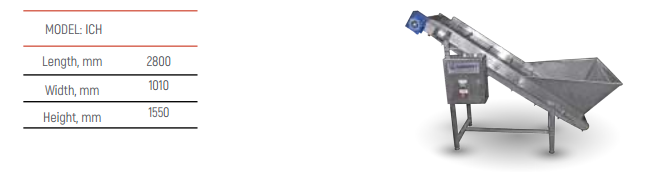

FEEDING CONVEYOR WITH HOPPER ICH – feeding conveyor consists of a hopper, the size of which is determined by the product, and the necessary output, and an inclined transporter, which ensures that the product is lifted and evenly transported to a place for further processing.The volume of the hopper, the width of the conveyor, the angle of inclination, the necessary length and the size of the edges is determined individually depending on the customer’s requirements. The speed of the conveyor belt can be optionally regulated with a frequency converter. Feeding conveyor can be manufactured in a stationary or in a mobile version.

AIR COOLING CONVEYOR CAC air-cooling conveyors are designed for intensive cooling of the products after frying, cooking or blanching, using blown air at an ambient temperature. CC ambient air-cooling conveyors effectively reduce the product temperature (in most cases in just a few seconds), immediately stopping the cooking process. The product is cooled to a temperature suitable for packaging. The design of the cooling conveyor ensures optimal air distribution across the whole area of the conveyor mesh. A high-performance industrial fan with power controls is set at the bottom of the conveyor and is included in the basic scope of supply