INLINE HOMOGENIZER | HIGH SHEAR MIXER

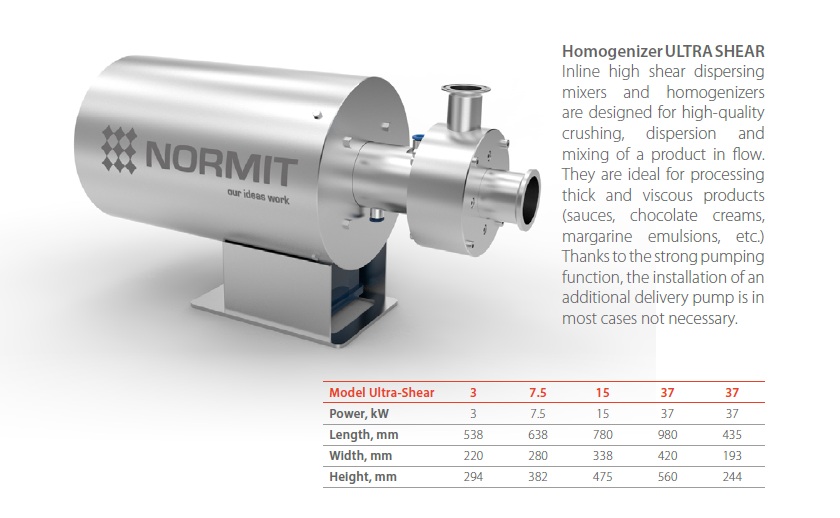

Models: Yumix Basic, Yumix MOL, Ultra Shear, Shark, Gydromix

Inline homogenizers are designed to be convenient and efficient part of the manufacturing line, providing you with powerful quality boost and the process intesity. To improve the efficiency of the mixing and homogenizing, these inline homogenizers commonly operate using a recirculation vessel. The required degree of homogenizing is accomplished after the material has went through the recirculation loop a few times.

Model YUMIX - this homogenizer works on a rotot/stator principle. The material is absorbed by means of the feed fitting, frequently through the feed pump and the rotor transfers it to the stator.

SHARK homogenizer – these types of inline homogenizers are constructed for achieving highly precise suspensions or emulsions. A uniquelly shaped rotor and the flexible gap between the rotor and the stator is allowing to accomplish a great level of homogenizing.

GYDROMIX homogenizer - these multi-chamber inline homogenizers are mostly constructed for structures of homogenization systems for manufacturing multi-component materials that are highly flexible for the manufacturing process. Dispersing mixers are constructed for the highest standard of dispersion, crushing, or mixing of materials. When going through the working part, the material is differently effected by the working components, which guarantees accomplishing a great degree of mixing, dispersion or reducing particles in only one phase.

Dispersing mixers - Benefits:

- Powerful performance.

- Efficient mixing and homogenizing.

- Can operate at higher temperature.

- Easy cleaning, maintenance.

- Short production time.

- High product quality and durability.

- Conserving energy, materials and processes.

For more information about our inline homogenizer, or for a free consultation, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.