Honey pasteurizer UTO 2000 | Beekeeping equipment

Designed for heat processing of 2000 kg of honey

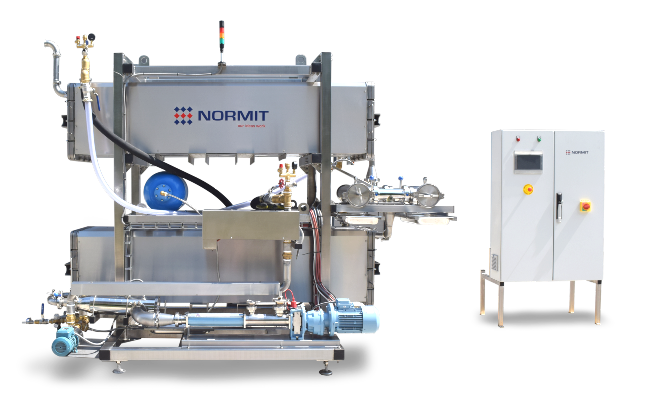

Installation of thermal processing and filtration of honey. The device is designed to process 2000 kg of honey per hour. The honey melting and filtration plant UTO is designed for the manufacture of high-quality natural products with good commercial properties and an attractive appearance.

WHY PASTEURIZE HONEY

If the honey you buy in the store is not labelled "raw", it is most likely pasteurized.

HOW TO PASTEURIZE HONEY - MELTING HONEY CRYSTALS IN A VERY SHORT TIME

Heating and cooling in a short time. Its main task is to warm the honey to to a temperature needed for pasteurization, in a short time, filter it - remove / melt the honey crystals and then to cool it, so that its viscosity is suitable for further processing (pumping, filling into trays ...) Melting of honey crystals happens in a very short time period.

Specially designed cooling system

The cooling of honey is handled by a specially designed hydraulic system, with a mixing hopper, chiller and a series of pumps.

Exchangers are easily disassembled, cleaned and re-assembled

Both exchangers are designed as high hygienic. Their construction is designed for simple disassembly, cleaning and re-assembly in a minimum of time (This is very rare with other exchangers)

Honey Processing Equipment - Technical features:

- Capacity up to 2000kg / h

- Heating system

- Pump for honey supply to the plant

- Control system

- Three way valve on product release

- Honey filter

Bee Equipment - Advantages

- The pumping device will pump the honey in a volume 2000 kg

- The honey is filtered through the first filter before entering the exchangers to collect the coarse dirt

- The heating of honey is secured with the hydraulic system

For more information on our honey processing equipment, or for a free consultation, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.