Honey dehydrator | Honey dehumidifier HDM - NORMIT

Model: HDM 75 / 150 / 600

To receive a quote, ask for the price or a free consultation, please email This email address is being protected from spambots. You need JavaScript enabled to view it.

The large surface for heat exchange in a compact design is due to the special shape of the agitator. Evaporation of water takes place continually over a large surface, which ensures fast and efficient drying of honey.

Mixing is performed at the same time as drying to evenly regulate the moisture of the entire portion of honey in the plant. The special shape of the agitator enables efficient mixing of different kinds of honey for creating a blend.

Filtration system. If filtering the honey is needed, it can be pumped through an external filter when it is discharged from the plant or a built-in filter can be supplied. The working body can be partially manufactured in the form of stainless-steel mesh or perforated.

If you need to intensely heat the product or melt crystallized honey, the HDM installation is supplied with a heating jacket for connecting to an external hot water system or with an internal heating source.

Honey processing equipment - Advantages:

- Universal application – a single plant performs mixing (blending, homogenizing), removal of excess moisture, and if needed, filtration.

- It’s economical. The efficient design allows it to perform all processes with minimal energy costs and in a minimum amount of time.

- Low cost and low maintenance expenses, minimal energy consumption.

- It’s compact. The plant has the greatest possible surface area for heat exchange over a small amount of space.

- It’s hygienic. The HDM plant is designed for convenient cleaning and maintenance. Clean-in-place can be carried out within the plant itself.

|

Model: HDM |

75 |

150 |

600 |

|

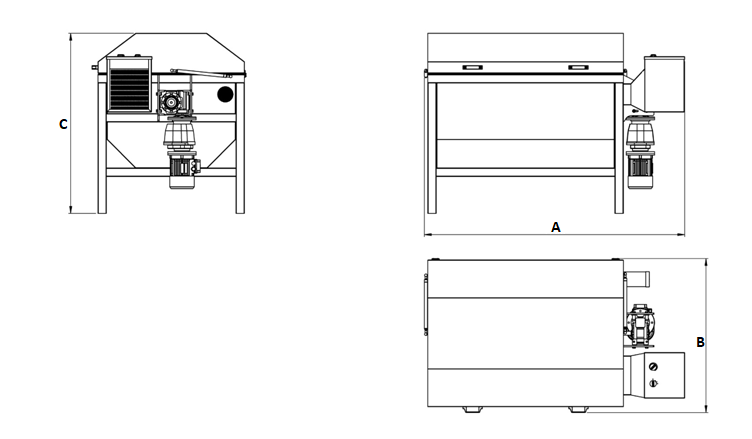

A: length, mm |

1 055 |

1 200 |

1 900 |

|

B: width, mm |

650 |

700 |

1 150 |

|

C: height, mm |

750 |

800 |

1 350 |