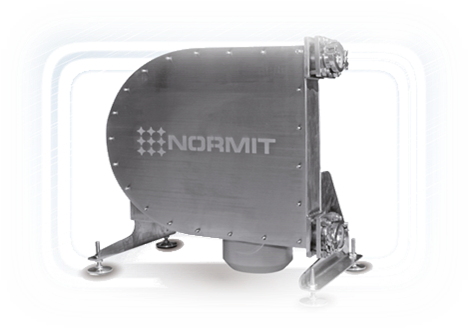

Hose pump

Hose pump

Hose pump

Hadicové čerpadlo

Hose pumps NORMIT PP are used in various industries: water treatment, mining, food, chemical, pharmaceutical and polygraphics industry

Hose pumps NORMIT PP handle abrasive, highly aggressive, viscous, sensitive materials and substances with high density. Innovative technology that eliminates the need for the presence of cooling and lubricating fluid inside the pump, the process is faster and more economical

Uses:

Hose pumps do not use the liquid coolant, that is not compatible with the application in the food industry, due to possible leakage. Pump is a versatile and efficient in all processes that require ease of use and accuracy in carrying out the transport of fluids, the great advantage is its self-priming ability up to 9 meters and also ability to work in a "dry„ conditions, pump is completely reversible

Advantages:

How it works

The basic structure and principle of hose / peristaltic pumps is very simple and can be simplified compared to the act which is automatically done when you are trying to push something out by hands of the tubing or casing. Because of the pumping principle all fluid media which "pass through the hose" can be pumped irrespective of whether they are abrasiv, aggressive or containing solids. This effect creates the high vacuum in the hose which causes suction and discharge of the media. The liquid being pumped never comes into contact with any moving parts because it is totally contained within the re-enforced hose that means fluids never come into contact with moving valves, springs or seals. Hose Pumps are self-priming displacement pumps which are safe to run dry. Therefore, this principle is ideal for use in sterile (hygienic) environment. It is ideal for pumping fine chemicals and food.

Specification:

|

N. |

MAX flow rate |

MAX flow rate |

Motor speed |

Voltage |

Energy consumtion |

Hose size |

|

1. |

L/H |

bar |

r/min |

V/Hz |

W |

мм (dxD-L) |

|

2. |

22 |

1 |

50 |

230V 50-60Hz |

40 |

8x12,8 |

|

3. |

100 |

1 |

150 |

230V 50-60Hz |

60 |

9,6x14,4 |

|

4. |

2 |

2 |

25 |

230V 50-60Hz |

4 |

4,8x9,6-160 |

|

5. |

10 |

1 |

108 |

230V 50-60Hz |

5 |

6x9-160 |

|

6. |

1,1 |

1 |

20 |

230V 50-60Hz |

3,5 |

4x7-110 |

|

7. |

3,3 |

1 |

60 |

230V 50-60Hz |

6 |

4x7-110 |

|

8. |

6,0 |

1 |

108 |

12V/24V DC |

4 |

4x7-110 |