Jam production line NORMIT

LINKA NA VÝROBU DŽEMU, MARMELÁDY

LINKA NA VÝROBU DŽEMU, MARMELÁDY

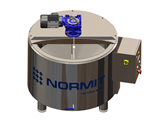

The line is constructed out of stainless steel, applicable for stirring and distributing fruit puree and sugar to produce jam. AISI 304 stainless steel tank, with glazed and pickled inside and outside surface,pickeled, Double jacket. Flat cover which could be open by pneumatic system , stirrer at low speed

Line for production of jam consists of the following parts

|

Installed power |

1, 5 Kw. |

|

Compressed air at 6 bars |

100 NL/min |

|

Steam consumption |

200kg/h at 0, 5 bar |

2. Automatic system to proportion

-it is possible to memorize different recipes, ) system to proportion the different ingredients

3. Sugar hopper

Made of stainless steel with a capacity of 500 liters, stainless steel- length of about 3550 mm, motor with a reduction of 1.5 kW, valve

4. Vacuum jam cookers unit volume 1500l

- Suitable for food industry

- The device is characterized by a convex bottom and a lid with a diameter of 1500 mm, manufactured in compact version, heat-insulated, pneumatic valve , Manual service valve

- Parts: manhole, , two sight glasses, lamp, safety valve, Anchor stirrer , gear motor installed power 2, 2 Kw, liquid ring pump, Pneumatic valve system , thermometer

|

Steam at 3 bar |

450 kg/h max consumption |

|

Electricity |

6, 75 Kw |

|

Compressed air a 6 bars |

50 Nl/min |

Condenser

Surface tube nest condenser, it is formed by a multi tubular heat exchanger into which steam is condensate for an indirect exchange with water in counter current.

Option

- Lights

- Filler

- Vacuum Glass

- Level sensor and temperature controller

- Chiller

- Cooling tower

Technical parameters

|

Maximal capacity – up to |

30.000 l / h |

|

Input water temperature |

38 ° C |

|

Output water temperature |

30 ° C |

|

Power |

380 V 3 phases 50 Hz |

|

Air capacity |

5, 42 m3 / s |

|

Instaled power |

3 kW |

|

Pump with a capacity of 30,000 liters to 2 bars with an installed capacity of 5.5 kilowatts |

√ |

5. Thermo conditioned tank volume 2000L

is thermally insulated and stabilized product to a constant temperature. The container is slightly inclined and is provided with slow stirring to maintain the homogeneity of the product. The product then moves to the next stage

|

Power |

2Kw |

6. Jam pump

Manufactured from stainless steel, suitable for food products, containers for storage of the product, change the speed can be adjusted manually, using the wheel

|

Consumptions: electric motors |

4kW |

7 Accessories

8 Control Panel

9 roller conveyors

10 Filling machine

Roller conveyor - stainless steel, aluminum rollers, length 2000 mm / for empty buckets

Filling system consisting of a stainless steel flow meter with an accuracy of 0.1% 'Easy maintenance and cleaning

Roller conveyor- for full buckets,

Connections, valves

Control system / PLC control Panel-

Production of approximately 120 pieces / hour

Product temperature of 40-50 ° C

11 Pasteurization tunnel

The jam or juice needs a pasteurization treatment to assure a long shelf life to the product., stainless steel frame with a tank placed on a stainless steel tubular trestle, One variable speed motor trough an inverter,

A series of system to support the transport belt

12. Unit to prepare the pectin solution

the tank (100l ), made from stainless steel will have the following characteristics

13. Lid platter

Closure system is complete with conveyor, conveyor is driven by inverters to adjust speed electrical length is about 2.5 meters, individually adjustable height and width of the lid, from 1 to 10 kg

14. Steam generator

standard design compact on one pallet, without water treatment plant, the water storage tank

|

Power |

500 kg steam / hod |

|

Working pressure |

to 5 bar |

|

Arc tube |

Two-stage |