Reactors for pharmaceutical industry

Over 20 years an engineering company „NORMIT s.r.o.“ practices a production of pharmaceutical facilities, specifically pharmaceutical reactors, bioreactors and fermenters.

Reactors for pharmaceutical industry

Manufacturing of equipment for pharmaceutical and biopharmaceutical industry is a very complex process. The „NORMIT“ company develops and produces reactors and bioreactors according to the highest EU standards of quality, safety, and hygiene. All equipment we produce has an EU-CE quality certificate.

Pharmaceutical reactors are used for carrying out chemical engineering processes: hydrolysis, neutralization, crystallization, evaporation, chemical transformations, dispersion, homogenization, dilution, thermal treatment of products and others operations

Reactors and fermenters are used extensively in pharmaceutical and chemical industry for producing substances, vaccines, ointments, gels, grouts, and such pharmaceutical products as insulin, antibiotics, and vitamins.

Fermenters or bioreactors are designed for cultivation of microorganisms at sterile conditions and constant temperature, mixing and forced-air cooling. Bioreactors are used not only in the pharmaceutical industry but also in the food industry, for example for manufacturing beer and yeast.

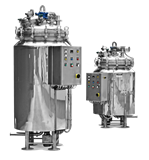

„NORMIT“ pharmaceutical reactors, hydrolyzers and fermenters

The pharmaceutical reactor consists of a triple-jacket vessel made of AISI 316L or AISI 304 stainless steel.

The standard configuration of the „NORMIT“ pharmaceutical reactor includes:

- Waterproof vessel

- Heating (cooling) jacket to ensure the effectiveness of thermal processes

- Temperature sensors

- Built-in heating elements or jacket for steaming

- Unloading hatch, a viewpoint with lighting

- Clamp junctions for variable rigging or pipelines

- A protective glass surface and purification system

- Different type of stirrers (anchor, turbine, propeller);

-

Mounting of the magnetic stirrer is possible

-

Homogenizers or dispensers

-

Control panel

It is possible to add configuration with a frequency inverter for continuous adjustment of mixer rotary speed, weight sensors for the reactor and flowmeter, sterilization in place system (SIP), an electronic display of stirrer rotary speed and other control equipment in compliance with your requirements.

It is possible to add configuration with a frequency inverter for continuous adjustment of mixer rotary speed, weight sensors for the reactor and flowmeter, sterilization in place system (SIP), an electronic display of stirrer rotary speed and other control equipment in compliance with your requirements. -

CAM and CAD systems have been applied for assistance in the development of products and application of new technologies. Thanks to these, we managed to secure the best quality products on the European market. The NORMIT s.r.o. engineering company is equipped with the precise and modern CNC facilities produced by such firms as „Okuma“, „Flow“, „Boldrini“,

„Messer“, „Fronius“, „Jutec“, „Trumpf“, „Davi“, „Megobal“, „LVD“, „Eckold“, „Grief“, „Comaca“, „BPR“, „Gornati“ and „Est Ticino“. Absolute sterility is extremely important for pharmaceutical and food industry.

„Messer“, „Fronius“, „Jutec“, „Trumpf“, „Davi“, „Megobal“, „LVD“, „Eckold“, „Grief“, „Comaca“, „BPR“, „Gornati“ and „Est Ticino“. Absolute sterility is extremely important for pharmaceutical and food industry.

Advantages of pharmaceutical „NORMIT“ vacuum reactors and fermenters

- We use materials and components from leading European manufacturers. It guarantees a high quality and durability of the produced equipment

- Individual and custom approach to each client allows us to manufacture equipment according to clients needs and possibilities.

If needed, we can provide: Control and documentation systems, Quality control documentation, Production test Validation, GMP paperwork.

In compliance with the GMP rules, the equipment for the pharmaceutical industry must meet the definite requirements. If required, a specialist from the „NORMIT“ company will provide you GMP documentation for a small fee.

Qualification and Protocols:

DQ — design qualification

IQ — installation qualification

OQ — operational qualification

PQ — performarce qualification

Operating instructions and user manual;

For more information please contact the sales department at This email address is being protected from spambots. You need JavaScript enabled to view it.