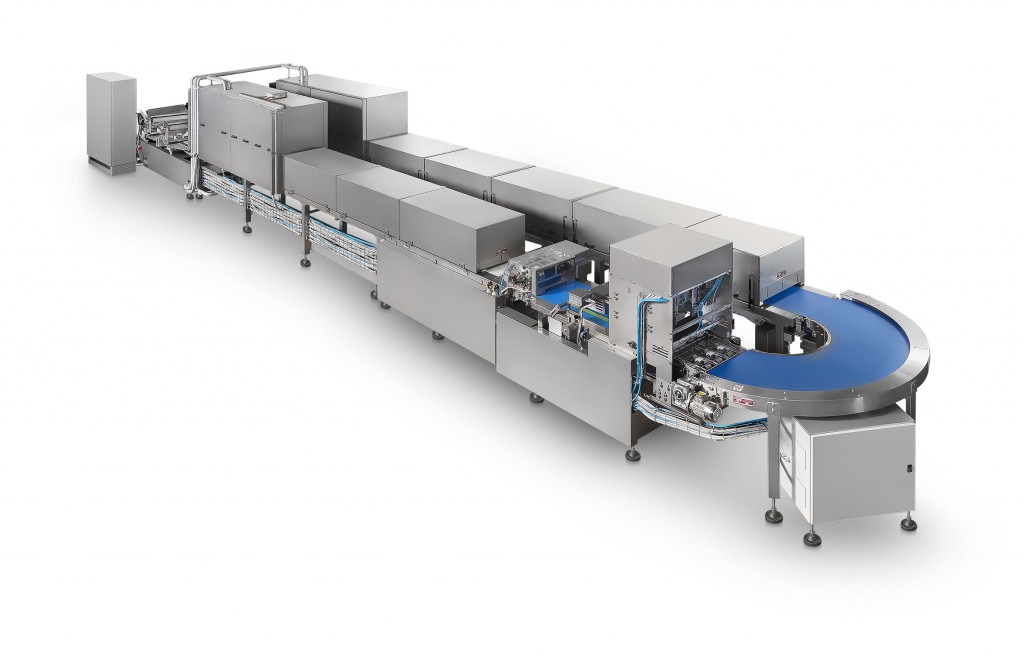

CEREAL BAR PRODUCTION LINE

Equipment used for the production of cereal bars capacity 40-100 kg / h

Line consists of:

- cooker (option vacuum cooker)

- stainless steel table

- cooling unit for the stainless steel table

- cutter for bars width

- cutter for bars lenght

1. Cooker

- It is used in the processing of the cereal material

- Flexible cooker with electric control

- A stainless steel vessel

- Stirrer- planetary construction

- Tilting system for easy unloading of products

- Enables cooking at low temperatures - thereby preventing caramelized mixtures

Option - speed rotation control

- includes inverter and potentiometer

Accessory:

container for transporting products

2: Stainless steel table ( Stainless steel table with integrated cutting and cooling unit)

Stainless steel table is completely made of stainless steel AISI 304 with a working area of 800 x 800 m

The table is equipped with an internal system for heating and cooling the product to the requirements of predefined recipes

Table 4 contains a sidewall to keep the cereal mixture on a work surface and set the final adjustable thickness of the product

Cooling system for stainless steel tables - refrigeration unit includes a reservoir containing water and glycol circuit pump liquid in a closed circuit and electrical cabinets with the thermostat to adjust the temperature

3. Cutter for cross cutting - 25 mm

- It is used for cutting the final width of the product. The device consists of a motorized shaft and moves along a stainless steel tables

- with 32 blades for cutting the final width of 25 mm

4. Cutter for longitual cutting 80 mm

- The device is designed for cutting lenght of cereal bars

- 10 blades for cutting lenght width up to 80 mm

- moves along a stainless steel tables

For more information about this product, please contact our sales department at This email address is being protected from spambots. You need JavaScript enabled to view it.