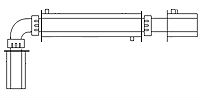

Heat exchanger- "tube-in-tube"

The device is used for the heating / pasteurisation of food products. It is used to transfer heat between the technological environment in various industries.

Principle

Chiller and cooling liquid circulate in the space between the tubes. Chiller / pasteurizer are used in wide range of temperatures and loads. The heat exchangers of this type consist of a number of series-connected units. Each one consists of two coaxial tubes. Double pipe heat exchangers with a larger heating surface is composed of several parallel connected parts. If the saturated steam is placed as a one of the chillers then is usually supplied to the annular (ring) space.

Benefits double tube heat exchanger

- High heat transfer coefficient

- Suitable for heating or cooling medium under high pressure

- Easy installation and maintenance.

Technical parameters

| dy MM | Dy MM | L max MM | L lin MM | d MM |

| 50 | 63 | 6000 | 1000 | 0,5 |

Can be adjustable.