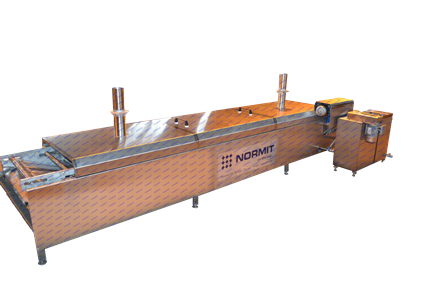

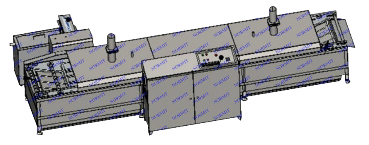

Conveyor deep fryer

Conveyor deep fryer combines effective design, high performance, simplicity and high quality frying.

the conveyor fryer is made for frying and deep frying vegetables, mushrooms, fast food, fries, chips, nuts, meat and fish, dumplings, onion rings, squid, crackers, popcorn, snacks, confectionery and bakery products, donuts, crackers, spring rolls and buns.

Processes:

- deep frying

- frying

- baking

- heating

Deep fryer NORMIT OIL fried products quickly, efficiently and uniformly. The oil in the fryer is heated to 150 to 200 ° C depending on the type of product to be fried. Frying takes just a few minutes. The resulting product has the same temperature, a uniform color and texture. Each piece is baked uniformly over the length of the conveyor.

The source of heat are electric heaters. Heating elements are advantageous in that they provide efficient heat transfer. This method of frying supplies 97-99% of the heat directly into the oil, which ensures a perfect finished product with you all the desired properties. Heating elements are advantageous in that they provide efficient heat transfer. The product passes between the lower and upper conveyor. he upper conveyor (retaining) provides continuous emergence of product.Baking time and temperature are adjustable.

Control system

Controling is ensured by automatic control (PLC), which is designed for more complex machinery, equipment and production lines, where it is necessary to record the temperature, temperature sensing, signaling limit parameters, take multiple values, automatic dosing, level control, time setting, monitoring, etc. There is also ability of connecting to PC, connect touch screen or conect to ethernet.

Benefits of frying in deep fryer NORMIT OIL

- Quality fried product is favorable to the flavor and aromatic characteristics

- With our deep fryers you can achieve uniform and homogeneous appearance of the final product

- The result is high quality and easily digestible final product

The fryer is usually placed in the technological line in part. The baked goods are further processed (mixing, freezing, packaging).

Deep Fryer Advantages

- Oil filtration system

- Oil circulation system

- Oil level check

- Adjustable belt speed

- The universality

- Easy operation

- Low cost Fryer

- High performance deep fryers and low power consumption

- Stable operation at high temperature and safety

| Size | A | B | C |

| NORMIT 1 | 1400 | 450 | 870 |

| NORMIT 2 |

2450 | 450 | 870 |

| NORMIT 4 |

3350 | 550 | 870 |

| NORMIT 5 |

4300 | 550 | 1000 |

| NORMIT 7,5 |

5000 | 1300 | 1660 |

| NORMIT 10 | 6480 | 2000 | 2060 |

| NORMIT 20 |

8450 | 1990 |

2240 |