Our company has rich experience in designing and manufacturing of vacuum equipment.

Our company has rich experience in designing and manufacturing of vacuum equipment.

Degassing-removing gas (vapor) from the tanks (tanks, boilers) to reduce the atmospheric pressure. This reduces the temperature of food processing (evaporation of the product at 42 ° C) increases the stability of the resulting product, while maintains the original color and taste.

Degassing is used in the food industry for the concentration of milk and milk products, fruit and vegetable juices, herbal extracts, pharmaceuticals (medicinal tea, biomass from bacterial cells, enzymes), waste of wine (nonstandard raw wine and many other products).

Advantages of vacuum equipments:

Advantages of vacuum equipments:

- reduce the temperature of the processed product (product retains its properties - color, flavor and vitamins)

- removal products and components using vacuum

- venting, reducing the oxidation product

- shortening process times (3-4 times)

- increase the life of the finished product

- obtain a stable homogeneous product

- the possibility of drying, evaporation in various industries

Vacuum containers are used in the process of mixing, homogenizing products:

- in the food industry (ketchup, mayonnaise, mustard, sauces, horseradish, desserts)

- In cosmetics (creams, shampoos, gels, toothpaste, detergents)

- pharmaceutical preparations (creams, ointments, emulsions)

- in the chemical industry (oil, paint, emulsion) and others.

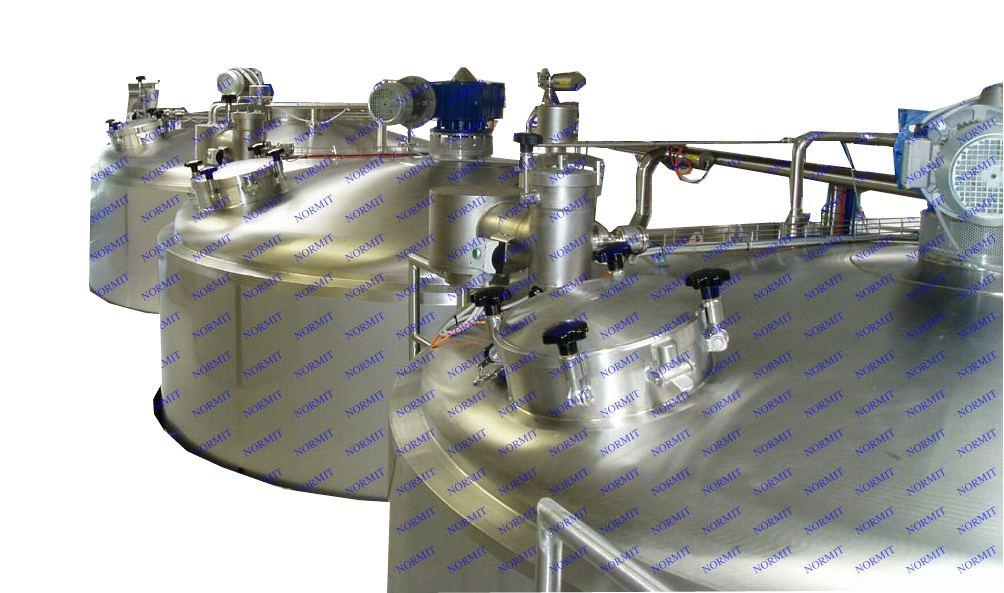

Vacuum containers are made of stainless steel, they can be double (jacket with the heat), (with the heat insulation and sheath), which is equipped with a pump. Homogenizer or other device are equipped with agitators of di fferent types (depending on the processed product), electrical heating (radiators) remote control.

fferent types (depending on the processed product), electrical heating (radiators) remote control.

|