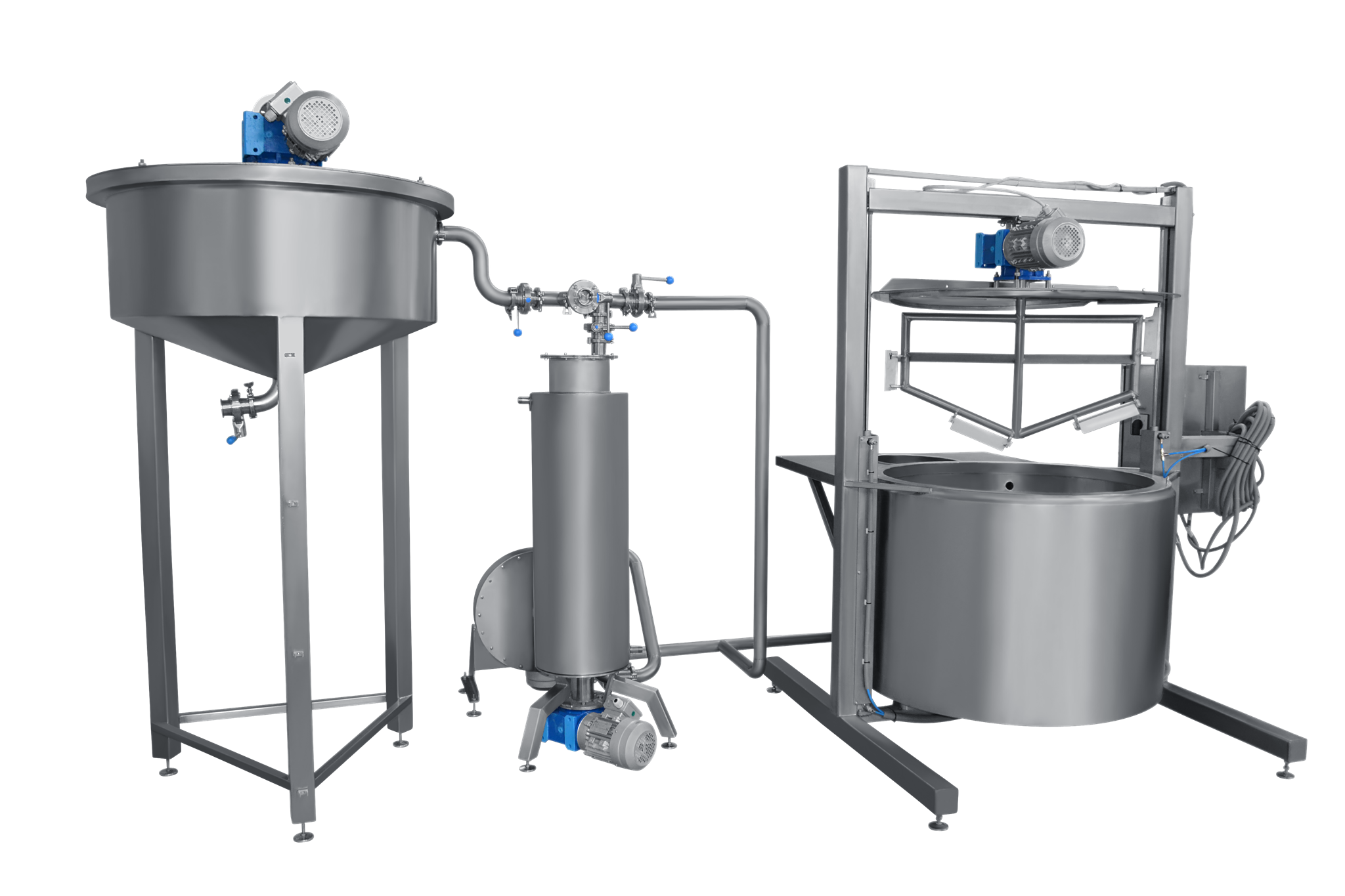

Yogurt production line

This unique homogenizing plant with a pasteurizing machine is constructed for many different materials, from fluid to high viscousity, with homogenized form or hard pieces of up to 15 mm (or larger on demand).

The plant enables these actions:

- cooking (atmospheric or vacuum)

- homogenizing

- stirring

- pasteurizing

- asceptic cooling (optional)

Models of manufactured material:

- Yogurt with bits, cream, dairy products

- Jam, marmalade, pickled containers

- Condiments

The line comprises of these machines:

1. Principal boiling / cooking device - atmospheric boiler 300 l with an electric heater and an agitator with Teflon scraper

2. Inline Homogenizer

3. Heat exchanger

4. Hose pump - working and care guidelines

5. Storing vessel with an agitator with Teflon scrapers

Atmospheric boiler with a working volume of 300 liters, a mixer Teflon scrapers, pneumatically controlled lid with 1/3 door, side container for adding product. Boiler is double jacketed with insulation, made of finest stainless steel AISI 304, heated with heating elements (6 pcs x 3 kW = 18 kW). Stirring of the product is provided by an anchor full-volume stirrer, an agitator speed of 28 rpm. The agitator drive is powered by a 1.5 kW motor. Product output is secured via a DN 50 pipe.

The inline homogenizer works on the rotor / stator principle. It is intended for mixing and homogenization. This model is suitable for the production of emulsions and suspensions. When emulsions are processed, the machine achieves a particle size of only 1 micrometer. Solid textures (powders) are subjected to a thorough dispersion of the particles. The homogenizer also fulfills the function of the pump, the product itself is brought to the homogenisation from the boiler. The homogenizer knives can be simply dismantled and replaced by others, making the homogenizer very versatile and flexible. The gap between the blades and the wall is designed so that the homogenizer can be easily cleaned.

3. Scraped suface heat exchanger

The scraped surface heat exchanger is a complex thermomechanical system consisting of a stationary heat exchanger which has a cylindrical shape with a central movable shaft. Teflon knives are mounted on the shaft to wipe the product from the cylinder walls, thereby increasing the heating / cooling efficiency. The heat exchanger must be connected to the pump to bring the product to the exchanger.

The product is moved into the exchanger through the lower valve and moves upward through the pipe. At the same time, the system delivers hot / cold liquid to the duplicator of the exchanger, thereby heating the product. The heat / cold transfer efficiency is achieved by increasing the rate of hot / cold liquid circulation. The heated / cooled product is fed through the upper output valve. If the product is not sufficiently heated / cooled, the valve opens and the process is repeated. The temperature of the product can be monitored on an analogue thermometer located at the top of the heat exchanger.

4. Hose pump

The hose pump has a simple construction and trouble-free operation. The medium does not come into contact with the moving part and is fully sealed in the hose. The rotor moves along the length of the hose and compresses it. With this movement, the pumped liquid shifts (positive displacement) and pushes out of the hose. Subsequently, due to the natural elasticity of the hose, it returns to its circular shape, creating a negative pressure, thanks to which the pump will be replenished

5. Storing vessel with agitator

Single jacket stainless steel vessel with a working volume of 300 l, with an agitator with Teflon scrapers and a temperature sensor. The vessel is made of stainless steel AISI 304. It is used to receive the cooled product from the main boiler, which has been homogenized and cooled and is ready for dosing.

Benefits:

- Flexibility - it is possible to process a big amount of material with various characteristics in one machine.

- Comfortable loading of material, simple care and washing.

- Hygiene - higher quality parts, comprehensive welding washing.

- Following the cooking mode, the machines are easily washed using detergents.

- Affordable - the stirring, cooking, homogenizing or pasteurising activities are done with highest effectiveness and minimum energy or time loss.

- Different sources of heating.

- Parameters changing and different available options.

For a free price quote, email us at This email address is being protected from spambots. You need JavaScript enabled to view it.