Melters

Melters are used for solid or molten fat frozen blocks of animal and vegetable origin (butter, margarine, cocoa butter, chocolate sauce, etc.), and keep them in a molten state at a certain temperature.

It is used in industry for the production of margarine, mixed oil, ice cream, condensed milk, filled, creams, ointments, oils, etc..

Products:

- In the food industry: oil, spreads, ice cream, margarine, chocolate frosting, preparation of condensed milk filling, butter

- In pharmaceuticals and cosmetics: creams, fats, ointments, gels,

Processes:

- melting

- heating

Melter is triple-jacket tank, mounted vertically on the legs. Inside the melter are electric heating elements. The maximum temperature of the heating fluid is 150 ° C.

Controling

is ensured by automatic control (PLC), which is designed for more complex machinery, equipment and production lines, where it is necessary to record the temperature, temperature sensing, signaling limit.

Benefits

- quality construction

- low cost

- Easy maintenance and cleaning

- easy manipulation

Variants:

- Melter with electric heating

- Melter with steam heating

Technical parameters

| Model | NorMelter-0,1 | NorMelter-0,2 | NorMelter-0,3 | NorMelter-0,4 | NorMelter-0,6 | NorMelter-1,0 | NorMelter-1,6 |

| Volume, l | 100 | 200 | 300 | 400 | 600 | 1000 | 1600 a viac |

| Power, kW | 12 | 20 | 20 | 24 | 32 | 45 | 61,5 |

|

Heating time, min

|

15 to 60 | ||||||

| Speed, rec/min | 0 to 150 | ||||||

| Material | AISI 304, AISI 316 | ||||||

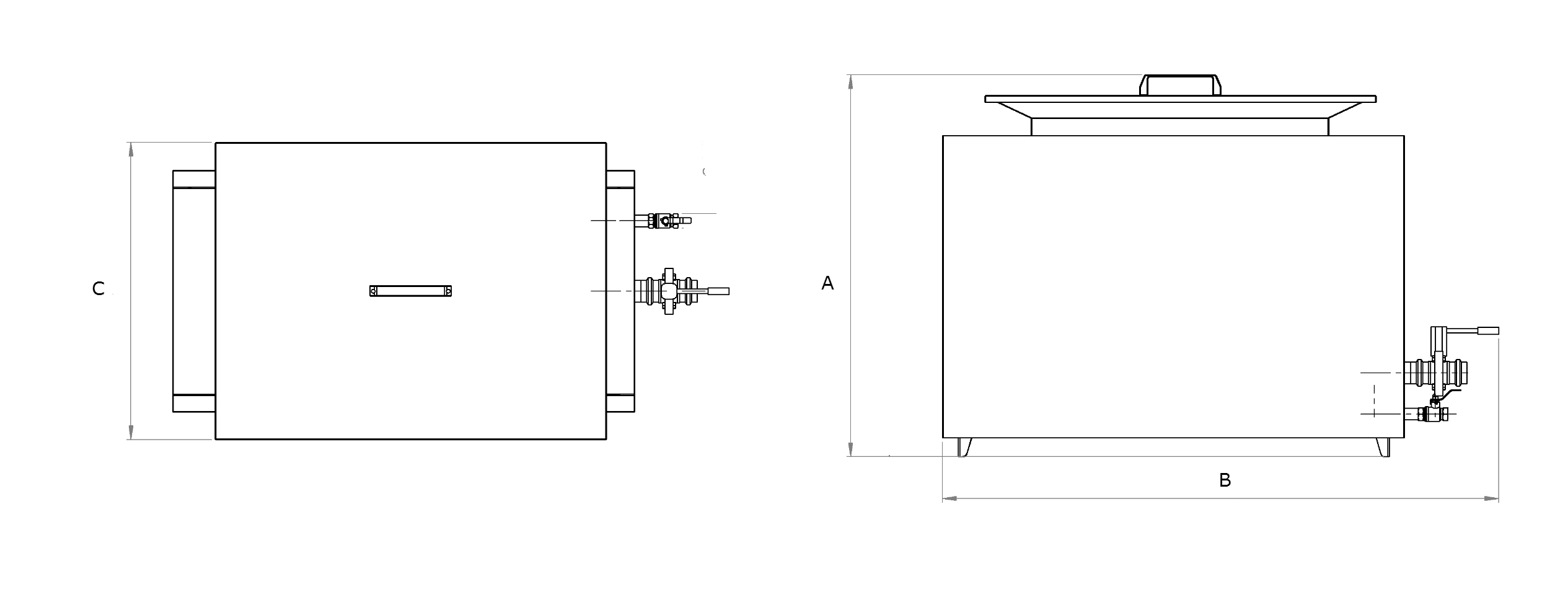

Dimenzions

|

Dimenzions mm

|

NorMelter-0,1 | NorMelter-0,2 | NorMelter-0,3 | NorMelter-0,4 | NorMelter-0,6 | NorMelter-1,0 | NorMelter-1,6 |

| A | 300 | 460 | 560 | 820 | 580 | 915 | 860 |

| B | 950 | 1000 | 1500 | 1360 | 1520 | 1333 | 1530 |

| C | 350 | 360 | 360 | 380 | 710 | 712 | 740 |