COOKIE DEPOSITOR / COOKIE MAKING MACHINE

Cookie machine intended for the production of unlimited variations of cakes and cookies of various types.

We have different types of cookie machines for different types of cookies. For more information, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.

Cookie depositor can be used as a machine for processing many types of pastry doughs like shortcrust pastry, choux pastry, puff pastry, sponge cake for products such a sponge cake sheets, shortcrust pastry sheets, brownies, eclairs, cupcakes, muffins, macarons, choux buns, lady fingers, biscuits, cookies and many more.

Cookie making machine is suitable for many other applications involving cream dispensing and can be also used as a cake decorating machine. Having a cake machine for the pastry production in the bakery or pastry shop allows for significantly streamlined process, increase of productivity and expansion of the product range.

BISCUIT MACHINES WITH DIFFERENT DOSING HEADS

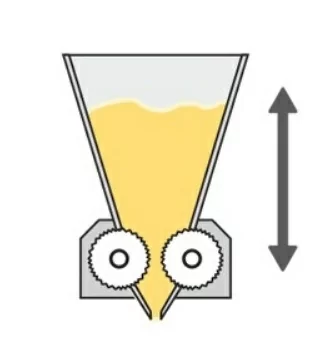

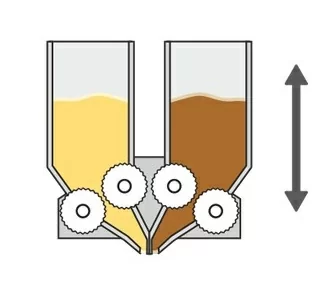

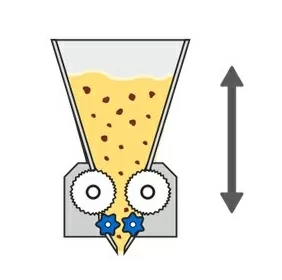

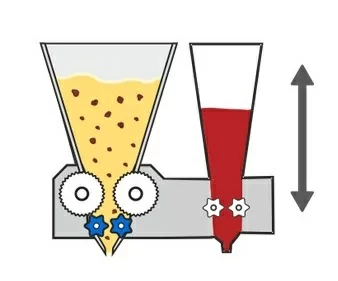

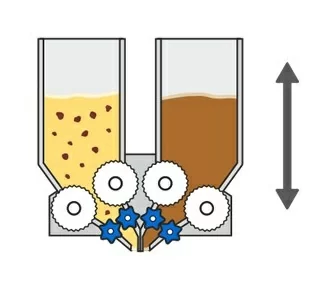

Cookie machines have a unique design based on the use of dual pumps (PLUS versions), a mobile dosing head, and a conveyor at a fixed height, which greatly increases their capabilities. When choosing a biscuit equipment, you should consider the amount of dough colours, if filling dosing is required, the size of trays, the type of pastry and the product range to be produced.

COOKIE DEPOSITOR BENEFITS:

JCD cookie maker is a solid semi commercial equipment constructed for medium or large capacity bakery.

Semi automated sweets equipment was constructed for manufacturing of sweets from lighter dough (cakes, cream puffs), thiner dough (sponge cake). If equipped with extra pump, machinery may be applied for working with thicker material with added ingredients (coconut) plus for producing of foodstuff. A device is made in various addaptations processing 1 type of dough, 2 types of dough at the same time or 2 forms of dough plus filling (trio).

Cookie maker containing touch screen controller

Control Panel supplied with touch screen, enables staff to choose working mode, to add or alter settings determing a form, size plus manufacturing automation. Arranging plus altering of particular equipment settings is accomplished naturally, together with controlling of locations plus motions of operating components. Stability along with repeating actions are secured by induction engines plus precise regulation and measuring systems.

Manufacturing options of the equipment are split into five parts, that may be altered in ninety nine modes. Whole motions of the equipment posses changeable modifications in all sides of each edge and each stroke (regulated by exact guidelines).

This depositor may make forty strokes / m. Putting together components of the pump, funnel, system of spinning the nozzle or different kinds of spouts is quite simple and you can achieve it fairly shortly. Putting together the components after washing requires only a very short time. The equipment may be equipped with wire slicing system.

Benefits of a cookie depositor JCD:

- solid framework

- many different basic or unique devices containing the hopper for thiner dough and diaphragm hopper for material slicing with concurrent closing

- easier components exchange

- effortless washing of all components in touch with the material

- lengthened material building capabilities and functions using microprocessor controller with bigger volume of remembrance

- available extra tool for decorating cakes by rising and decreasing dosing and forming tool

COOKIE MACHINE JCD ONE

| MODEL | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD ONE 40 | 40 | 2.1 | 230V, 50Hz | |||

| JCD ONE 45 | 45 | 30 | 2.1 | 230V, 50Hz | 270 | 75 x 105 x 165 |

| JCD ONE 60 | 60 | 40 | 2.1 | 230V, 50Hz | 320 | 75 x 120 x 165 |

COOKIE MAKING MACHINE TWO

| MODEL | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD TWO 40 | 40 | 2.5 | 230V, 50Hz | 75 x 120 x 165 | ||

| JCD TWO 45 | 45 | 30 + 30 | 2.5 | 230V, 50Hz | 270 | 75 x 120 x 165 |

| JCD TWO 60 | 60 | 40 + 40 | 2.5 | 230V, 50Hz | 320 | 75 x 120 x 165 |

COOKIE DEPOSITOR ONE PLUS

| MODEL | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD ONE PLUS 40 | 40 | 2.4 | 230V, 50Hz | |||

| JCD ONE PLUS 45 | 45 | 30 | 2.4 | 230V, 50Hz | 290 | 75 x 105 x 165 |

| JCD ONE PLUS 60 | 60 | 40 | 2.4 | 230V, 50Hz | 350 | 75 x 120 x 165 |

COOKIE DEPOSITOR COMBI PLUS

| MODEL | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD COMBI PLUS 40 | 40 | 3.0 | 230V, 50Hz | |||

| JCD COMBI PLUS 45 | 45 | 30 + 15 | 3.0 | 230V, 50Hz | 270 | 75 x 105 x 165 |

| JCD COMBI PLUS 60 | 60 | 40 + 15 | 3.0 | 230V, 50Hz | 320 | 75 x 120 x 165 |

COOKIE MAKING MACHINE TWO PLUS

| MODEL | Trays width cm | Hopper capacity L | Power kW | Power supply | Weight kg | External dimensions LxWxH cm |

| JCD TWO PLUS 40 | 40 | 230V, 50Hz | ||||

| JCD TWO PLUS 45 | 45 | 30 + 30 | 3.3 | 230V, 50Hz | 370 | 75 x 105 x 165 |

| JCD TWO PLUS 60 | 60 | 40 + 40 | 3.7 | 230V, 50Hz | 420 | 75 x 120 x 165 |