Cereal bar produktion line contibar

LINKA NA VÝROBU CEREÁLNYCH TYČINIEK

LINKA NA VÝROBU CEREÁLNYCH TYČINIEK

CONTIBAR production lines are suitable for products made from fat materials soft and cooked sugar, carbonated water, fat and sugar, and materials of different mixtures of wheat flakes, muesli, nuts, cereals, fruits, seeds, also fitted with nuts, puffed rice, corn puffs etc.

Muesli base

The basic version consists of uncooked oatmeal and fruit.

Basic version:

1 DRY

The first kind of muesli is a loose powder mixture of mainly rolled oats and various pieces of dried fruit, nuts and seeds.Typically includes other cereals, such as wheat or rye. There are many kinds of muesli, for example, honey, flavoured with various spices or chocolate.

2 FRESH

The second type of muesli ready mix oatmeal with juicy / fresh basis. he usual ingredients include fresh fruit chopped s or grated into the pieces (eg. Bananas, berries, grapes, mango), dried fruit, dairy products (eg. Yoghurt, milk), lemon juice, grated nuts, seeds, spices (especially cinnamon) and honey.

Enrobing

Bars can be supplemented and combined with yogurt or milk, making them as important sources of protein.

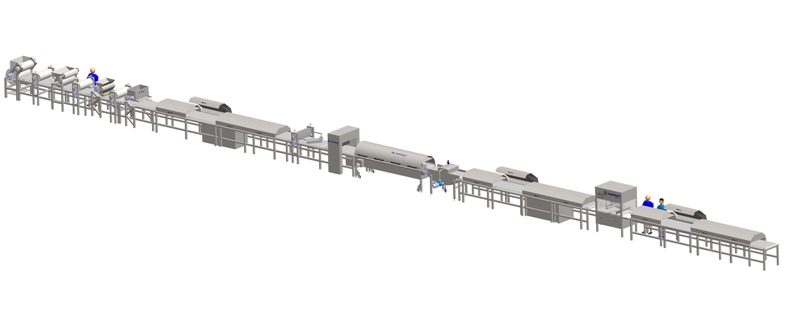

Line consist from:

1- Kitchen - cooking part

2 Mixing and homogenization

3 Formation

4 The extruder

5. Cooling tunnel

6-longitudinal cutter

7. Spreading system

8. Gilotine

9. Dispersion Machine

10. Enrobing

11. Cooling Tunnel

12. tempering system

13. Control System

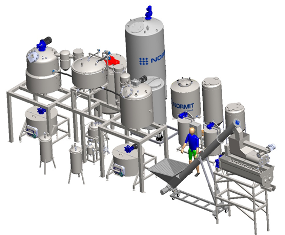

KITCHEN

Composition kitchen depends on the recipe.

MIXING AND HOMOGENIZATION

The process of mixing and homogenization has great influence on the final structure

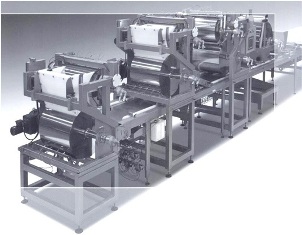

FORMATION

The mixture is passed through a systematic drums, where is the layer pressed into the preset dimensions. Standard can be customized thickness range from 5 to 30 mm. The machine is also suitable for processing fine, creamy and slightly aerated mixtures.

EXTRUDER

Designed for mixing and shaping of various solid, viscous and pasty products. Gives the format of the final product due to slow crowding product under pressure.

COOLING TUNNEL

Cooling tunnel made of stainless steel is used for the cooling of the product. It works by cooling the bottom as water-contact cooling and cooling the top with cold air. Of course there is easy maintenance and cleaning.

LONGITUDINAL CUTTER

We supply special cutting and forming equipment, cooperating with the design according to customer requirements. The process of cutting includes three part- Cutting machine, a system for spreading and system for the cross-cutting device.

Longitudinal cutter is responsible for the proper form a output.

SPREADING SYSTEM

The system prevents re-sticking of the shredded product back to each other.

GILOTINE

The device for cross-cutting into individual pieces. utting speed can be up to 120 cuts per minute and can be done mechanically or by means of an ultrasonic cutter.

ENROBING

For each application we offer a suitable method for enrobing