Potato chips production line

NORMIT s.r.o. invents and produces different types of machinery for the food, cosmetic, chemical, pharmaceutical and building sectors. We are experts manufacturing of processing machinery, placing higher requirements on quality while paying unique attention to introducing of innovative technologies.

For a price quote, please email This email address is being protected from spambots. You need JavaScript enabled to view it.

The Crisps making line consist of:

1. Fresh potatoes hopper and Feeding lift

2 Drum Washer

3. Slicer machine

4. Inspection conveyor

5. Washer

6. Drying machine

7. Fryer

8. Flavouring and salting machinery

9. Coater

Stainless steel

Improved productivity with excellent product quality.

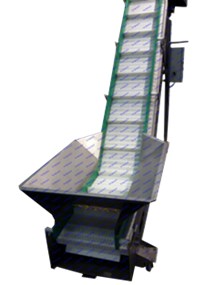

1. Fresh Potatoes conveyor with hopper plus feeding lift

The feeding of fresh potatoes into the manufacturing line may be done in different methods. We provide our own kinds of feeding equipment. The NORMIT fresh ingredient conveyor with hopper is constructed out of stainless steel. The ingredients are then transported into drum washing machine. Our standard control box units have been designed to control the hopper level sensing in harmony with the feed system in a single compact unit

2.Drum Washing Machine

Drum washing machine removes stones with clay dirt by rotating the drum. The process is called pre-washing Practical operating performance by the rate of contamination of potatoes

4. Potato cutter

Following the treatment of washing the washed potatoes are transport via screw conveyor into the potatoe cutter. The cutter is constructed out of higher quality materials, our range is applied for slicing of potato. The cutter has 2 amendable speeds. Volume of the cutter is 500kg/h of fresh potatoes.

5. Inspecting conveyor

The inspecting conveyor is created using higher quality stainless steel. The belt is made of PVC food. It is white, so the product is better checked. The product automatically gets into the sorting zone conveyor belt along its sides standing (sitting) personnel who visually checks whether the product is suitable or not. Dirt and wrong products are manually removed through the openings in the basket which is on the edge of the conveyor. A suitable product is deleted at the end of belt. The inspection conveyor is equipped with a light that enhances the quality of classification. The modular belt is white so as to raise the quality of the sorting

6. Washer with mesh belt at the end of the washer

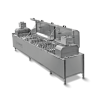

7. Continuous Paddle Fryer

The paddle fryer is designed for blanching through a screw motion system. The material is loaded into the feeding channel located at the entry of the blanching plant. The material is immersed in a higher temperature oil basin, when moving through the whole length of the plant thanks to a screw motion of the wheel. At the completion of the frying process, the material is put on an angled wheel granting dispensing of most of the hot oil.

Lastly, the product is raised thanks to a feeding conveyor where it undergoes more treatment.

For optimizing frying treatment the fryer is equipped with pumps for oil circulating. The settings like: oil temperature or frying time are automatic thanks to the control panel. The machinery ensures hygienic manufacturing and easy entry for washing intentions. Only stainless acid-proof steel AISI 304 or accepted plastic components are approved to get in contact with the material.

7. Conveyor with drying knife system

The Normit series air cooling conveyors are made for intense chilling and removing of water or oil from the product following frying, cooking or blanching, blowing air.

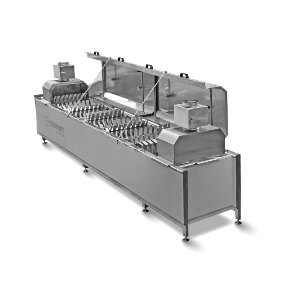

8. Flavouring and salting machinery

Mechanism suited for applying of arid materials such as salt, spices, flavors, additives and many others. The machine is used for coating different snacks such as crisps, fried snacks and others.

How it works: the material is continuously fed over the receiving hopper into the dragee drum, using specially shaped scrapers product gently flips and moves to the outlet of the drum thanks to the adjustable angle of inclination. At the same time there is a uniform supply of oil-and microcomponents through one special nozzle. Filling of the product is up to 30% of the drum volume.

For more information on our chips making production line, or for a free consultation, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.