VACUUM EVAPORATOR UFO 100 | JAM MAKING MACHINE

Vacuum evaporating is the method of reducing the pressure in a vessel beneath the steam pressure of the fluid, which makes the fluid to evaporate at reduced temperature than standard. Even if this method can be used for any kind of fluid at any steam pressure, it is mostly described as the water boiling by reducing the tank's innner pressure beneath a typical atmospheric pressure and making the water to boil.

If you apply this method to products, the water evaporates and is removed, you can store the final goods for a longer time with no spoiling. (source)

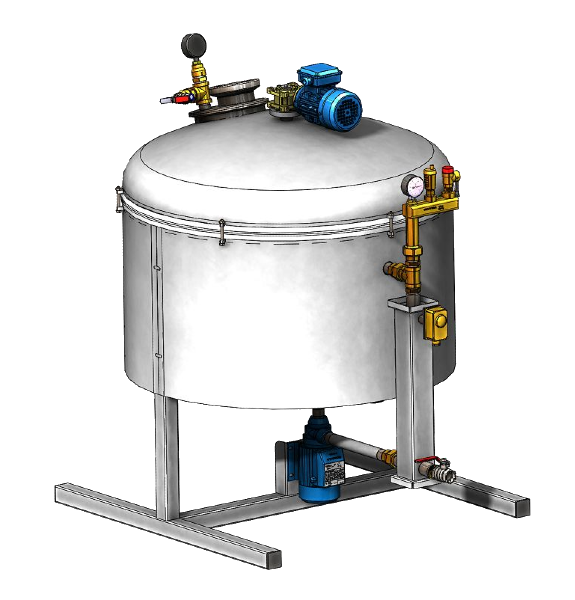

Vacuum Evaporatoring machines has been constructed to cook many different viscous materials under vacuum, when the process of boiling happens at reduced temperature. With this method, the organic flavour, smell and color of the product is retained.

Vacuum Evaporating machine - Suitable products:

- sirup

- condensed milk

- jam

- must

Jam making machine - control pannel:

- Basic - you are able to set the desired temperature while manually switching on vacuum

- Semi automated

- Fully automated with relay logic

- Fully automated with PLC

Longer product shelf life

Vacuum efficiently eliminates air bubbles from the final product. Ready meals obtain a homogeneous form with no air inclusions, and that significantly effects the shelf life of the final product.

Abbility to amend the evaporating machine and saving costs

Evaporation of evaporable liquid until the desired final product density is reached. High machine modularity - it is possible to adjust the machine according to the required modules, it will save money because it is possible to throw out modules that are not interesting for the customer.

- Electric heating

- Steam

- Circulating pump

- Pump for mixing and drain

- Hydrodynamic mixing

- Vacuum unit - suction (ejector)

- Vacuum Unit - Vacuum Ring Pump

- Condenser + condensate collector

- Agitator - manual stirring

- Agitator - stirring using motor

For more information on our vacuum evaporating equipment, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.

For information in Russian language please follow the link вакуум выпарная установка