Industrial dryers NORMIT

We provide the following types of Industrial dryers NORMIT.

for more information contact our sales department: at This email address is being protected from spambots. You need JavaScript enabled to view it.

FLUID BED DRYER VKD is a universal device for drying granules, sand, aggregates, salts, paste-like materials and similar materials for pharmaceutical, chemical, food and other related industries. The vibrating fluid dryer is characterized by the high performance with optimal energy use. Vibration prevents product layering and crater formation. The feed material to be dried is fed to the dryer from the feeder and is continuously moved horizontally through the force of the vibrations. The hot air is blown upward through the fluidized bed on which the product is placed, which heats and removes moisture. The dried product is removed from the dryer. The device has a smooth and clean internal area without dead zones, suitable for the pharmaceutical industry, the ability to produce according to GMP requirements.

DRUM DRYER HADD is a universal device for drying granules, sand, aggregates, salts. The warm air is fed into the dryer via a flex hose. The tilt of the drum is manually adjustable by the hand wheel.

CONVECTIVE DRUM DRYER ABM 9 is a convective air-drying device. It works on the principle of drum rotation and hot air flow. Dryers are designed for dry, loose materials and can be used for continuous and discontinuous operations. The device is equipped with a 4-stage tilting system of the drum.

Drying and crystallization machine is a device used for drying milk, yeast. The drum is heated by a duplicator. It is possible to adjust the thickness of the dried layer with a knife; a scraper at the end of the drum, scrapes the product down.

CONDENSATE FRUIT DRYER CFD is an effective way to reduce the humidity (in such products as fruits, vegetables, mushrooms, tea, etc.) with the minimal energy use. A condensing drying is a process where the air humidity is reduced in the sealed vessel. The moisture drops are formed on the outer surface of the evaporator due to the lower condensation temperature, so the water can be drained or collected to an external reservoir. The air temperature can be set at 40-50°C. The air circulation during the process ensures an achievement of a perfect result, even if the process is carried at low operating temperatures.

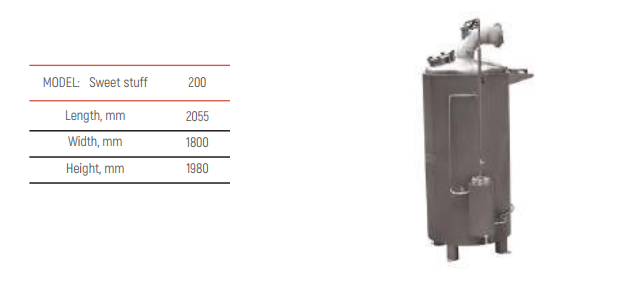

Spray dryer NSD is a closed system for evaporating the solvent, separating the desired substance, increasing its concentration in the solvent or completely removing the solvent (water). when drying the oil. The device is usually equipped with a spiral stirrer. Spray evaporator is an automated closed system for solvent evaporation to separate the substance (glycerin): increasing its concentration in the solvent or completely removing the solvent (water). The device is intended for the use in the chemical and pharmaceutical industries.