Z-Arm Mixer - NORMIT

Model: Z Sigma Arm

Z-Sigma Arm blade mixer is designed for intensive mixing, kneading, and plasticizing products with high and very high viscosity. Sigma blade mixer are among the most effective and efficient types of mixers.

Examples of applications:

- Chewing gum base

- Dough

- Toffee mass

- Soap base

- Adhesives

Design:

The sigma blade mixer consists of a bowl enclosed on all sides that is mounted on the frame. There are two horizontal shafts inside the bawl with Sigma-shaped blades rotating in opposite directions. Depending on the product’s properties, it is possible to use different shaped blades, as well as two installation methods. For products having medium to high viscosity, overlapping Sigma blades (overlapping trajectories) are typically installed, and the speed of both of the blades in this case is identical.

When mixing products with ultra-high viscosity, two blades are mounted tangentially. The motion path of the blades does not overlap, and the speed is different for each blade.

Mixing the product under the influence of the Sigma-shaped rotary blade is subjected to considerable shear deformation to ensure the uniform distribution of the ingredients, and the high shear stress and contraction provides not only an efficient mixing of the mass and grinding, but it also disperses the particles in the mixture. Using tangentially mounted blades enhances this effect.

The rotation speed of the blades can be adjusted using the optional inverter. The product can be loaded by removing the cover or through the pipe branch. The prepared mixture can be unloaded manually by turning the operating container or with a screw. The product can also be discharged through an extrusion die.

As an option, the mixer can be equipped with a heating or cooling jacket, manufactured for vacuum applications or for working under excessive pressure.

The mixer bowl is designed with the minimum number of welding seams. There are no sharp corners or dead zones in which product can accumulate. As an option, the mixer can be equipped with an air seal shaft that eliminates the dismantling and cleaning of the agitator seals.

Application:

A wide range of options allows you to choose the sigma blade mixer ideal for each application:

- Different shapes of blades

- Blades installed tangentially or overlapping

- Variable speed of the blades

- Heating and cooling jacket

- Product can be discharged manually or by overturning the bowl at a slope of up to 140 °, also with reverse tilt up to 140 °

- Product can be discharged through the extrusion head

- Product can be discharged with a screw

- Hatch for loading ingredients, supply of additional components

- Air seal shaft

- Vacuum performance

- Explosion proof version

- Stainless steel AISI304, AISI316, carbon steel, or other materials on request.

Advantages:

- Possibility of selecting the most suitable configuration for each application.

- A wide range of options.

- High reliability and performance.

- Highly hygienic design for use in the food, pharmaceutical, and chemical industries.

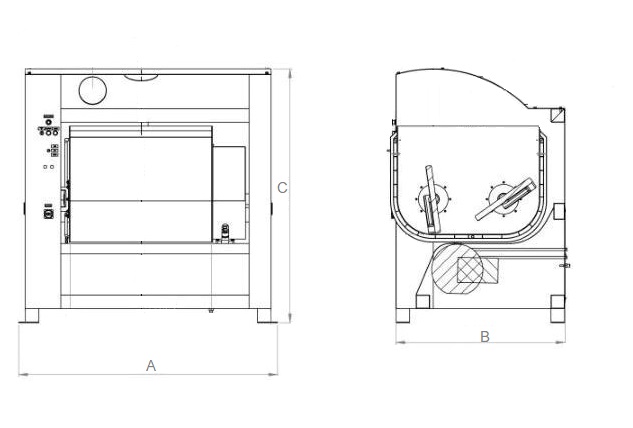

Dimensions:

A: 1 920

B: 1 754

C: 1 881