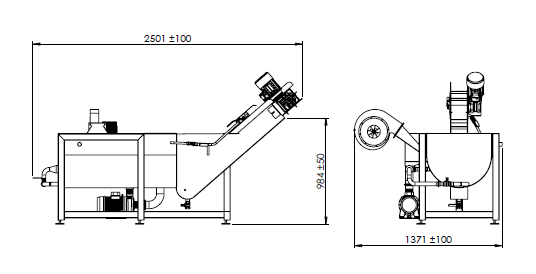

Bubble washing system

Vzduchová umývačka / Vegetable air washer

MACHINE DESCRIPTION

Washing machine is constructed as a compact unit consisting of the following components:

- Washing bath (basin)

- Air bubble circulation and washing system

- Working platform

- Modular discharge conveyor

- PLC

WASHING BATH (BASIN)

The width of washing bath can be adjustable by customer requirement. The bath is in the middle divided into two parts. In the first part coarse impurities are captured, the second part work as a filter tank on which bottom is placed perforated grid.

Both parts of the baths are equipped with drain valves and are easy to clean. Small impurities are captured by filter of water pump before discharge

Function of vegetable air washer

- diping function (submersible dipping of products)

- conveying function ( which ensures the forced displacement washed vegetables on a conveyor belt)

FILTER TANK

The filter tank is located on the down part of basic. There are captured all coarse impurities which flow through the basin

DISCHARGE MANUAL CONVEYOR

the belt widt are adjustable / usually is the width 600-800 cm. It is used for transporting of washed vegetables from the washing machine to the other technological devices.

THE WATER CIRCUIT

The circuit is made up of water circulation pump, water distribution and noozzles. The nozzles are adjustable, so it is possible to direct the water flow to the surface or towards the bottom, according to the washed product with regard to whether it floats or sinks. Water jet from the nozzles ensures displacement of the product being washed with washing mechanism.

THE AIR CIRCUIT

The air circuit consists of air blower and air distribution. The blower provides air bubbling across the entire working of the washing tub.

CONTROLING

is ensured by automatic control (PLC), which is designed for more complex machinery, equipment and production lines, where it is necessary to record the temperature, temperature sensing, signaling limit.

Technical parameters of machine

| Material | AISI 304 |

| Dimenzions, l, w, h | 4025,800, 1790mm |

| the angle of the conveyor | 45 |