SOLUTION FOR MAKING VEGETABLE CHIPS

The latest food trend gaining popularity in the market are innovative food products. The vegetable chips are considered to be healthier and tastier as many vegetables fall under the superfoods category. The appeal for non-GMO ingredients is high because of increasing cases of diabetes, gluten allergy, obesity, diabetes, and other similar diseases.

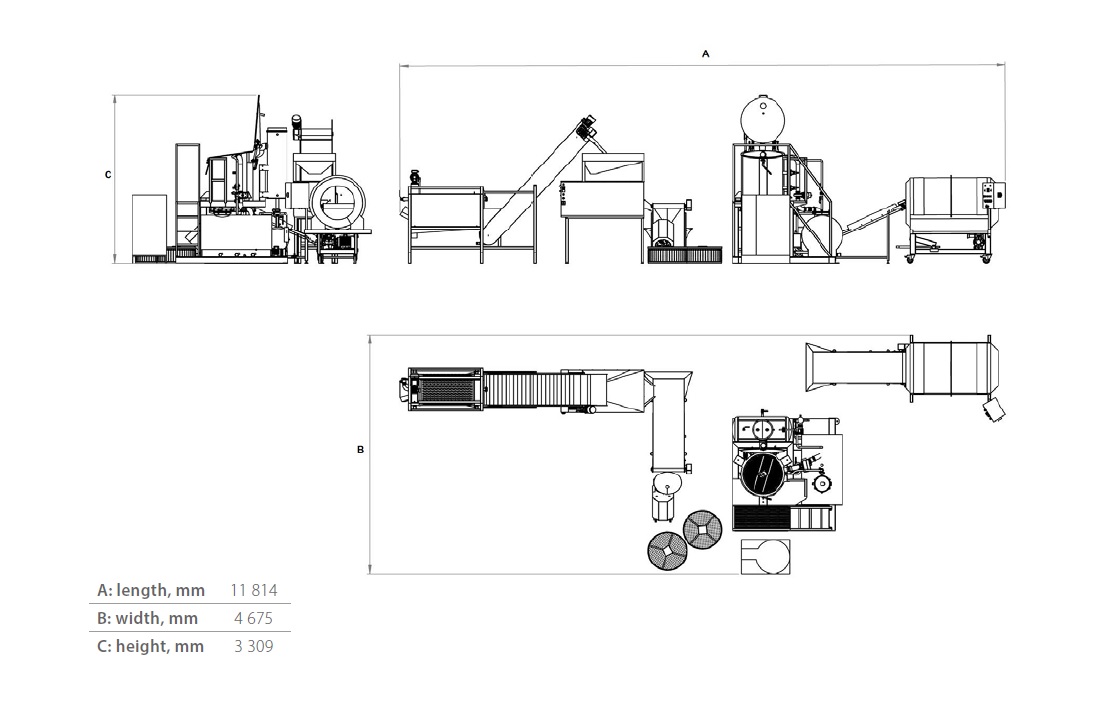

The technological line for vegetable chips

The line is intended for the complete processing of vegetable chips. It consists of a complex of devices that allow processes such as: pre-wash, total washing, brushing, slicing, vacuum frying and packaging.

For more information or to ASK FOR PRICE, please contact our sales department at This email address is being protected from spambots. You need JavaScript enabled to view it.

The line is designed for complete processing

raw vegetable to chips or french fries. The

result is healthy flavored products. In this line it

is possible to process different kind of vegetable

such as potato, beet, carrot, parsley and many

other. The final product can be flavored by salt,

spices or other flavors.

Your new product fried in a vacuum fryer will be:

- Nutritious

- Economical

- Delicious

- In demand

- Innovative

"According to the report, one of the major drivers for this market is Changing taste preferences. Manufacturers introduce new flavors of vegetable chips to expand their consumer base. The major flavors of vegetable chips around the world are roasted or toasted, barbeque, spice, and beef. Many players try to differentiate their products based on flavor; hence, it is an important component of vegetable chips. Barbeque is the predominant flavor in North America and Europe. The demand for this flavor is slowly picking up in APAC and is expected to grow moderately over the forecast period." (https://www.prnewswire.com/news-releases/global-vegetable-chips-market-2017-2021-manufacturers-introduce-new-flavors-of-vegetable-chips-to-expand-their-consumer-base-300579041.html, Jan 08, 2018)

The complete line for making vegetable chips includes:

1. Drum washer with conveyor

The product is loaded into the washing machine mechanically, after processing (washing) the product is unloaded using a conveyor elevator.

2. Brush washer

The device is suitable for washing root vegetables such as carrot, beet, potatoes. The product is washed through the built-in brush.

3. Conveyor with hopper

The hoper and conveyor are made of stainless steel. It transports product to the cutter.

4. Vegetable cutter

Rotary continuous root cutting device for slices: discs/rings (chips).

5. Vacuum fryer

Frying under vacuum conditions (at low

temperature) is a unique and cutting-edge

heat treatment method.

6. Conveyor with hopper

The hopper and conveyor are made of

stainless steel. The material is then transported

into drum coater.

7. Drum coater

Drum coater is suitable for flavoring product.

The cylinder (drum) operates continuously.

The role of vacuum in producing snacks

Vacuum drying and frying is an alternative method of making high-quality fruit and vegetable chips. Our professional staff’s knowledge, experience, and expertise allow them to manufacture the very best equipment

in this area.

The main details that determine a product’s quality are its structure, color, taste, and oil content. Under vacuum processing, the product’s structure is not harmed, as it is not subjected to mechanical action. Frying is

carried out at low pressure, which lowers the temperature that the oil boils at. This allows you to produce snacks at low temperature, which makes the end result crunchy but preserves the natural color, taste, and nutritional properties.

The removal, by means of vacuum, of air and oil from the pores in the product brings a number of advantages. The lack of air in the snack’s pores during processing lowers the time needed to prepare it, which boosts your output. Removal of oil from pores after frying gives a high-quality finished product, with a minimal oil content

– compare this to the standard processing approach in an atmospheric fryer where the oil content can reach 30–40%.

The vacuum drying and frying technology developed by our company’s experts, allows you to offer consumers a healthier and delicious product. This is especially relevant today for consumers who care about good nutrition.

An important detail to know about vacuum processing of chips and other snacks, is that frying at low pressure is carried out at low temperature and requires less oil. As a result, the snack that results will not contain acrylamide

and other carcinogens.

Retaining the natural taste and color of fruit, vegetable, and other chips lets you reduce the amount of taste

enhancers and food coloring applied, or avoid using them at all.

For more information or to ASK FOR PRICE, please contact our sales department at This email address is being protected from spambots. You need JavaScript enabled to view it.