Chocolate production line | Chocolate making machine

The chocolate making line is an automated mechanism for creating chocolate, chocolate glaze and filings.

Principle of operation:

The premixing system is based on the concurrent stirring of fresh ingredients and their heating. Homogenizing unit with heating and feeding hopper is fitted with horizontal vessel with engine and blade inside. The melted fat gets into the homogenizing device through the pipes where it is completely smashed and stirred. The homogenizing device forces the material back into the premixing tank. Material circulating is a continual closed mechanism. The homogenizing time is depending on the precondition of the material. A feeding hopper is fixed to the homogenizing device, through which large pieces are fed, mixing with the homogenous fat mixture. Through a closed pipe mechanism, the stirred chocolate mass in the homogenizing premixing mechanism is circulated, allowing a high er level of dispersing of the material.

Following the completion of the fresh ingredient homogenizing process, the material enters a spherical ball mill with a pump.

The aim is to keep the correct temperature and form by stirring the fresh ingredients for another processes. The stirring speed is regulated by frequency conventor.

The complete line has a heating mechanism comprising of a heat exchanger, circulating pump and pipeline joined to the baskets by warming up all the systems. Temperature regulator ensures temperature controlling of the manufacturing line. The needed temperature can be set.

Complete line includes:

1. Premixer with melting grid

The premixer consists of a vertical cone container with a geared motor, a rotary anchor mixer with Teflon scrapers, a melting grate. The melting grid is a closed heating system, which includes a grate.

2. Ball mill with heating jacket

Plant comprises of a vertical tubular tank, a geared engine, balls, a paddle mixer and double covering. Following processing, the material is moved to the premixer or to a storing vessel.

3. Storing vessel

For chocolate mass or glaze storage, with jacket heating and lower speed frame anchor mixer with Teflon scrapers.

4. Heat exchanger

The entire line has a single heating system consisting of a heat exchanger.

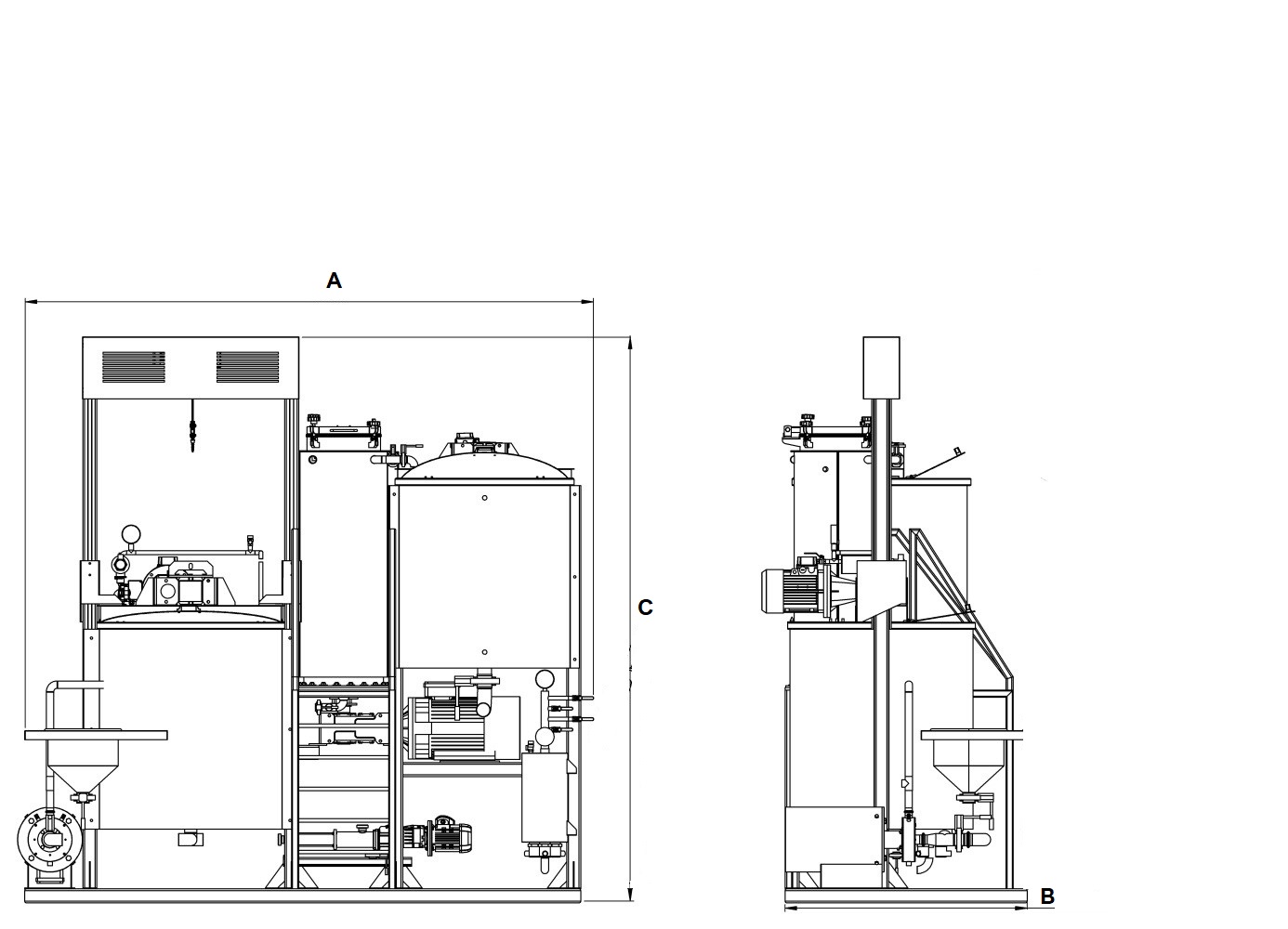

Dimensions:

A: 3 300 mm

B: 1 379 mm

C: 3 300 mm

Advantages

- The higher quality of the machinery. The machines is fully constructed from stainless steel, ensuring a long service life of the manufacturing line. The machines are hygienic and simple to wash.

- The higher quality of the final chocolate, due to the careful processing and smart temperature regulation.

For a price quote, drop us an email at This email address is being protected from spambots. You need JavaScript enabled to view it.