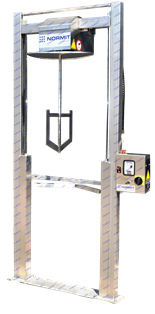

Universal disperser

NORMIT DISPERSER/ AGITADORES

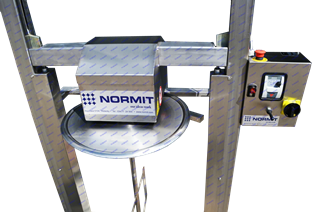

Universal dissolver (disperser) can be used with a high speed stirrer, with a slow speed stirrer also homogenizer or pump.

Processes

- Constant stirring in containers

- Homogenization

- Pumping

- Dissolves,

- Deagglomerates,

- Disperses,

- Emulsifies

Uses

- pharmaceutical industry

- chemical and cosmetic industry

- food industry

The Disperser is designed to distract, break out the dry ingredients (pigments, dyes and other materials), in liquid to obtain a suspension, emulsions and pastes with a high degree of dispersion. The blade imparts high shear forces to the ingredients being dispersed, breaking them apart. The dissolve (disperse)r distributes the liquid to solids (dissolve). High Speed Dispersers are perfect for viscous dispersions

The system allows three process:

- wetting of solids in a liquid

- mechanical grinding and separation of particle clusters

- the stabilization of newly formed small cells and prevents their re-flocculation (aggregation).

Process is important for the formation of a homogeneous mixture of a single structure with a stable biological activity.

Principle

To use dissolver, we have to lift him and put the container under the dissolver. The stirring unit is a on the frame of device. The mixing is carried out in a closed volume. Motor with gearbox is located centrally.

The impeller has an adjustable height. Lifting can be- pneumatic, hydraulic or electromechanical.

The two cylinders are placed in the side columns.

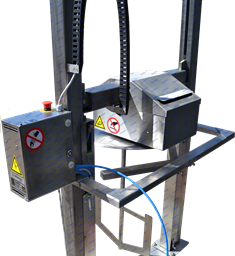

Controlling

Manual control is designed for simpler machines and technological equipment, which the technological process is not complicated and therefore do not need complicated programming. Simple operation using the ON / OFF.

Controlling is ensured by automatic control (PLC), which is designed for more complex machinery, equipment and production lines, where it is necessary to record the temperature, temperature sensing, signaling limit parameters, take multiple values, automatic dosing, level control, time setting, monitoring, etc. . When automatic control can copy entries to the PC, the ability to connect touchscreen or connect to ethernet.

Benefits

- Versatile - suitable for a wide range of products, suitable as a device for emptying the tanks (thanks submersible pump)

- Universal device - use with homogenizer, stirrer, pump

- Speed stirrer- adjustable

- Easy to use, easy to cleaning

- Stainless steel AISI 304, AISI 316

- Low maintenance costs

- The containers may be of different size and design, can be provided with jackets for heating or refrigeration

- Possibility to produce different versions

- The possibility of producing a high-speed stirrer

The unit is composed from (designed for batch size from 10-500 L ( or according the customers needs)

- three phases motor with PTC resistors

- with a variable by driving motor on frequency conveyor, the speed of the organ is continuously adjustable

- With constant power in the top range of speed and with speed - control, so that disperser is

safe against overload - For fixing on the wall.

- Lifting device to adjust the mixer disc in height infinitely by hand, with

low-friction guided tour, counterweight. In working position the unit will be fixed by looking

screw. The lifting device with adjustable security limit switch - With quick coupling for changing the organs and protection device, with

security limit switch. - With clamping device to fix the vessel, with manual operation by hand wheel and safety

switch

Options

- Design to work with vacuum

- Monitoring temperature

- Frequency converter and automatic speed control

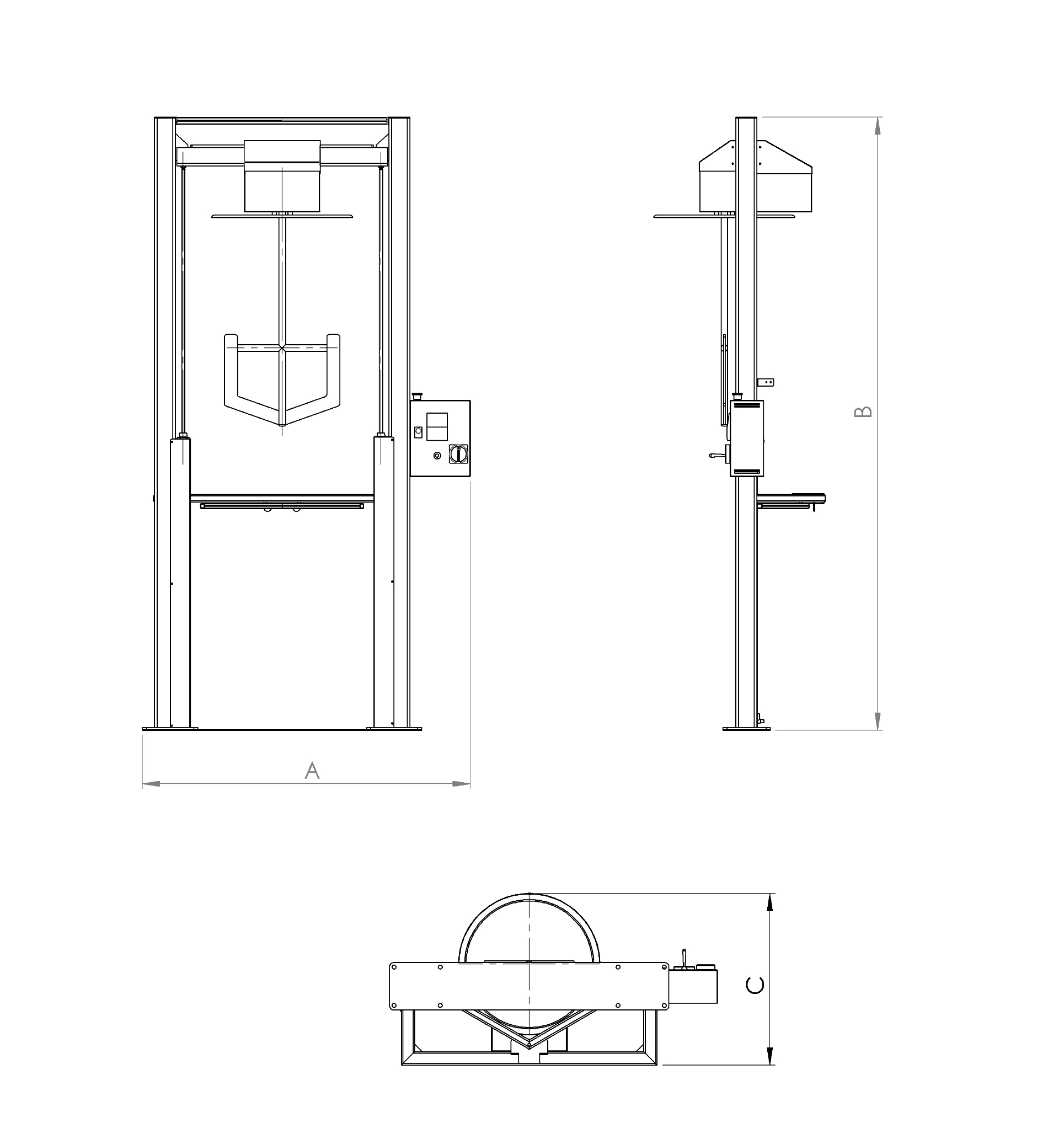

Dimensions and technical parameters

| Volume of vessel * | 10-500 |

| Stirrer material | AISI 316 |

| Material - other parts | AISI 304 |

| Mixer speed, rev / min (adjustable) | 0 ÷ 100 |

| Performance gear product | 0.25 kW ÷ 7.5 |

*vessel not inluded