Heat exchanger -scraped surface NORMIT

Теплообменники скребковые NORMIT

NORMIT company develops and manufactures a variety of equipment for the food, cosmetic, pharmaceutical,

chemical and other industries. We are the market leader in the production of technological equipment.

NORMIT Delta T Heat Exchangers provide a consistent and careful treatment of different kinds of food and drinks, as well as cosmetics and pharmaceutical materials. These scraped surface heat exchangers are designed to operate under hard conditions where other heat exchanger technologies can fail or cannot sustain operate efficiency over a longer period.

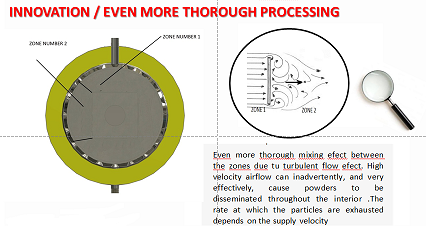

In the treatment of homogeneous products without solids (or particles to be crushed) in the design of heat exchangers can be used Normit TurboScraper shaft special form, which provides an additional effect homogenization

Designed for efficient heating and cooling of liquid, sticky, pasty or non-homogeneous products, including high viscosity and solids content in the chemical, petrochemical, and other industries.

Scraped Surface Heat Exchangers are more innovative compared with other types of heat exchangers, owing to the fact that the coefficient of removability from the heat transfer plate product is very high.

Processes

- Heating

- Aseptic cooling

- Deep- cooling

- Crystallization

- Dissolution

- Sterilization

- Pasteurization

- Polymerization

- Gelation

- Condensation

- Concentration

- Tempering

Applications

- Food and Beverage

- Pharmaceutical industry

- Cosmetic industry

- Chemical Industry

Scraped Surface Heat Exchangers NORMIT Delta T are commonly used for the following products:

|

Confectionary |

Fruits |

Sauces, dressings, condiments |

Meat |

|

Creams |

Puree |

Pesto |

Pate |

|

Syrups |

Smoothies |

Tapenade |

Ground-meat |

|

Ice creams |

Fillings for pastries |

Dressings for salad |

Pet food |

|

Marshmallow |

Chutney |

Salsa |

|

|

Waffles |

Applesauce |

Hummus |

Cosmetic |

|

Jelly |

Маrmelade |

Tartar sauce |

Vaseline |

|

Fondue |

Cheese sauce |

Wax |

|

|

Sweets |

Dairy |

Marinara sauce |

Gels |

|

Chocolate |

Cream cheeses |

Sauces |

Lotions |

|

Caramel |

Cottage cheese |

Marinades |

Ointments |

|

Cream |

Cranberry Sauce |

Emulsions |

|

|

Yogurt |

Tkemali |

||

|

Milk |

Mustard |

As well as |

|

|

Pudding |

Barbecue sauce |

Eggs |

|

|

Butter |

Starch |

Mashed potatoes |

|

|

Margarine |

Ketchup |

Peanut Butter |

|

|

Kefir |

Mayonnaise |

||

|

Curd |

We produce a standard Scraper Surface Heat Exchanger with an area of heat transfer from 0,1m2 (NORMIT Delta Lab) to 14m2 (NORMIT Delta 20) and a capacity of 10 kg / h to 10000kg / h.

How it works:

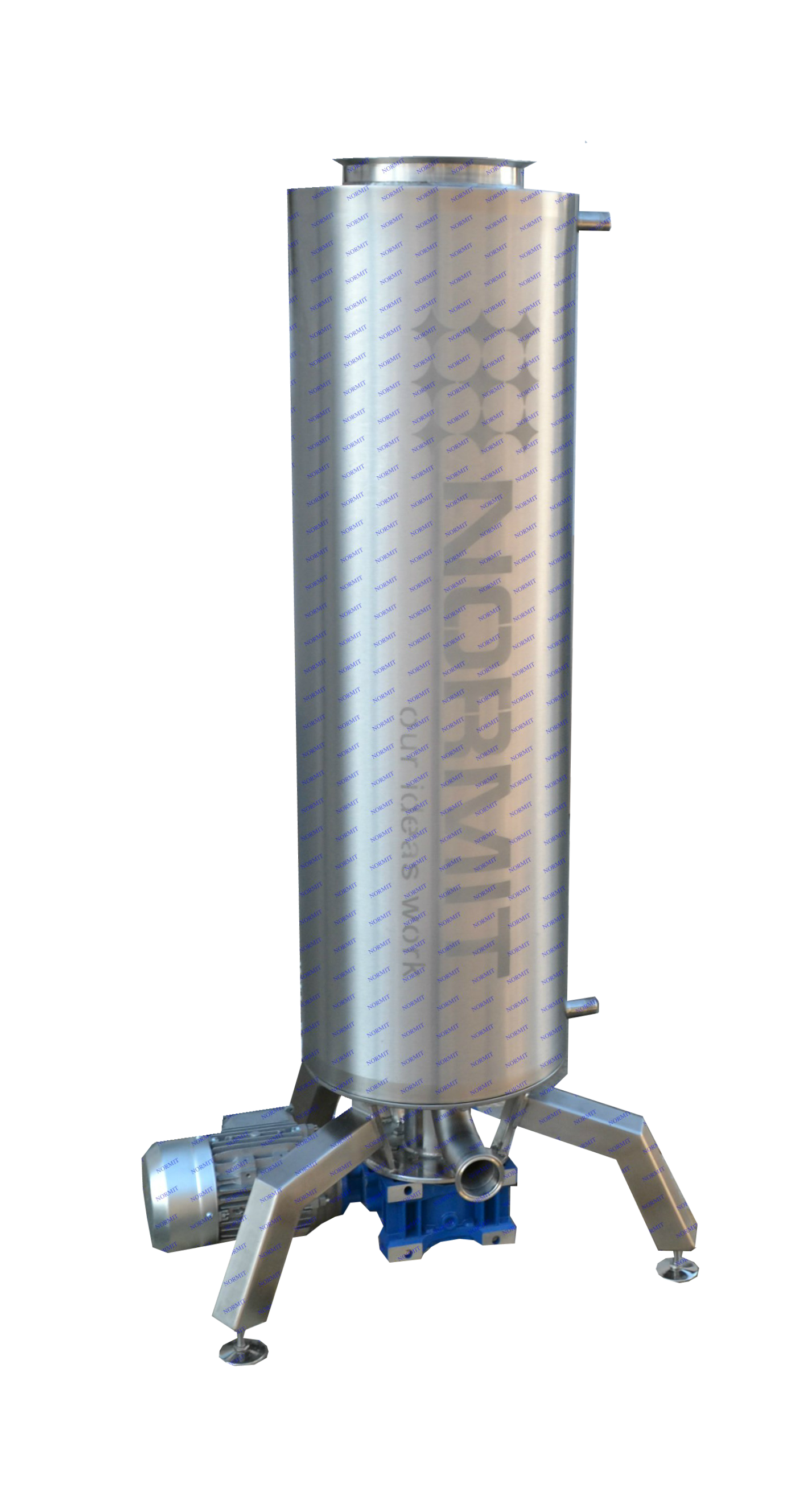

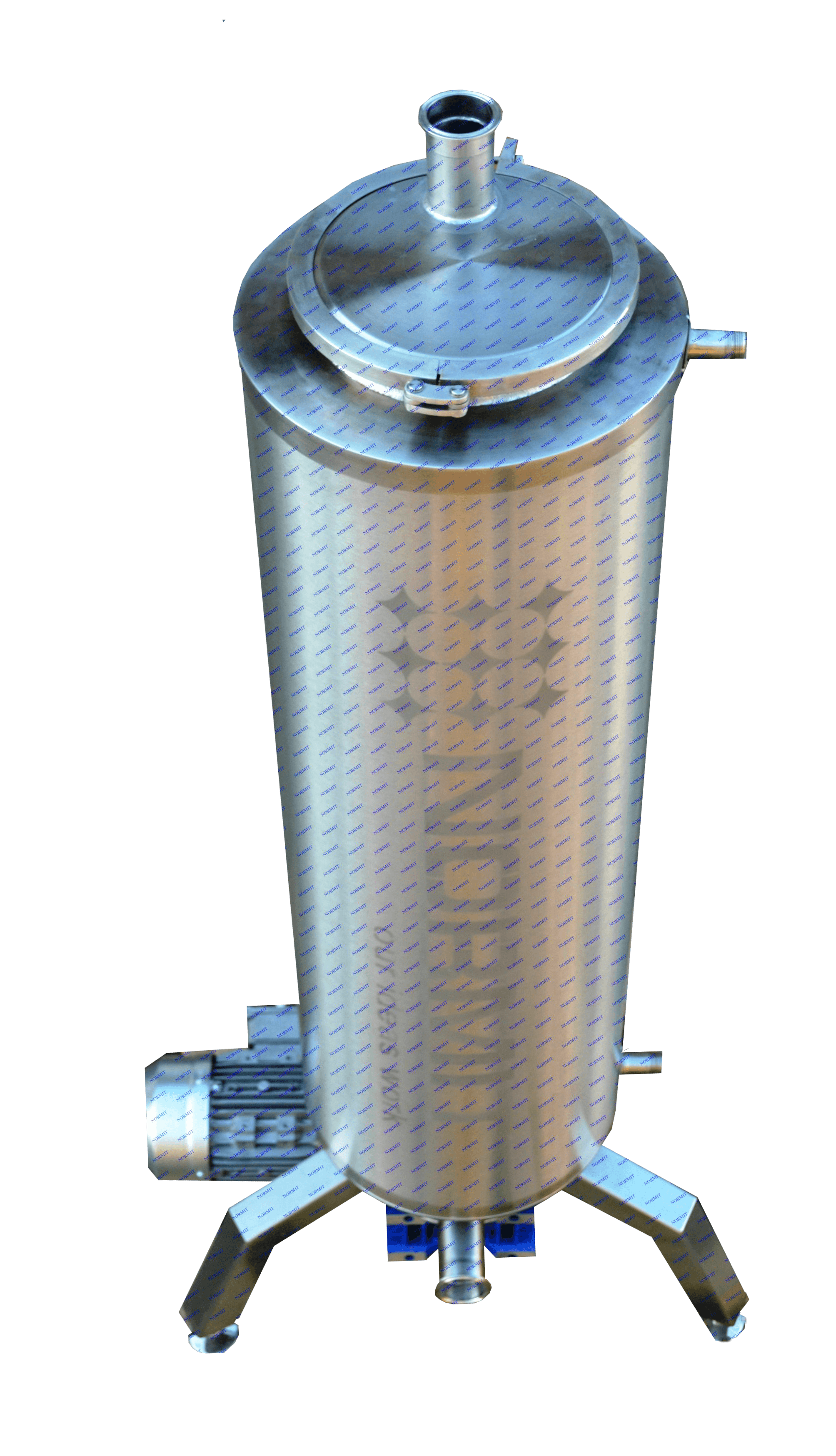

The heat exchanger is a complex thermomechanical system consisting of a stationary heat exchanger having a cylindrical movable shaft with a central or eccentric location- (relative to the tubular heat exchanger), fluoroplastic scrapers mounted on the shaft, the heat exchange jacket, insulation layer and an outer cladding.

Heat treatment of the product ongoing in the annular space between the inner and outer cylinders of heat exchanger

The scrapers during rotation are pressed against the inner walls of the cylinders, mixing and greatly improving the heat transfer process. As a result, the product in the operating area of the heat exchanger has a rotary translational movement.

The scrapers are made of high-tech materials that are not toxic and not damage the taste of the product and decrease its value in accordance with the standards of food

products.

Scraped Surface Heat Exchanger

NORMIT LAB / LABORATORIUM

CHEMICAL PROCESSING: HEATING AND COOLING, CRYSTALLIZATION

- Small batch sizes

- 40-100l/per hour

- Unique in their hygienic execution

- Inline heating and cooling

- All process parameters are under operator control for maximum flexibility

Available:

Dimensions:

Specifications may be changed in accordance with the technical specifications of the Client.

NORMIT HORIZONTAL/ PRESSURE HEATING

Scraped Surface Heat Exchanger

Horizontal scraped surface heat exchanger benefits from an equal loading on both bearings within the system ( in vertical design – all of the loading on the lower bearings. As the associated pipework within the system can be connected to either the front or the rear connectors, benefits can be made from having reduced pipework designed to optimize the system within the production plate.

Scraped surface heat exchangers horizontal model have been replacing slow, inefficient batching operations with more uniform, controllable and repeatable continuous processing.

Horizontal units can be mounted side by side with cylinders per frame or furnished loose for vertical mount.

The advantage of the scraped surface heat exchanger is that can process very viscous products with small particles. The process allows for reduce burn (depends on the type of the product) allowing for longer production runs.

The Vertical format can save floor space, depending on plant design and may be more advantageous in plants where is a little space

The scraper

The scrapers are made of high-tech materials that are not toxic and do not damage the taste of the product and decrease its value in accordance with the standards of food products. The chemical resistance is high, water absorption is low

Shaft of scraped surface heat exchanger

The amount of time the product is within the heat exchanger for a given rate is controlled by the volume of the unit. In that reason we produce small-shaft heat exchangers that provide a large annulus for longer processing time, they can handle lumpy products and those with large particles and also large-shaft heat exchangers with smaller annulus for high velocity and turbulence with high heat transfer rates and short product residence time in the unit.

BENEFITS

- Fast and highly efficient treatment of the product

- Customization, multiple options

- Efficient transfer of heat from the continuous scraping or the entire heat exchanged surface

- Continuity of the process eliminates scorching or freezing the product

- Are not provided with potentially dangerous materials such as chromium

- Vertical & horizontal configurations

- Delicate treatment of the product, which guarantees no damage

- Double-jacket construction can be used at low pressure and low speed, which is particularly important when processing of delicate products

- Easy Maintenance

- Quick and easy replacement of scrapers

- Does not require special hydraulic system

- Tangential entry / exit

- Can be combined with a CIP or SIP

- The lid can be opened with clips

- Low cost in comparison with similar models

- Highest quality materials all wetted parts are made of stainless steel of the highest quality European-made in AISI 304 and AISI 316 heat exchange surfaces

- Possibility of processing of the product with particles up to 1 inch

- The outer surface of polished steel or mirror

- Roughness of the inner surface up to ≤0,59 Ra

- Constructs a series of heat exchangers Normit TurboScraper easy to dismantle is convenient for cleaning and inspection.

- Casing has special channels, which can significantly increase the speed of the heat and cooling agent, which increases the heat transfer and increases the efficiency of the entire system.

More information you can find by the next link Heat exchanger scraped