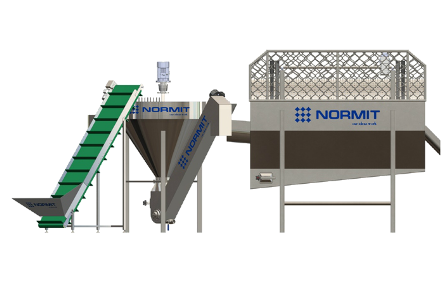

Frozen pea processing line

PRODUCTION LINE FOR MAKING FROZEN PEAS /Equipment for production of frozen pies/ for capacity 1000 kg/h

LINKA NA SPRACOVANIE MRAZENĚHO HRÁŠKU /Zariadenia na spracovanie mrazeného hrášku / pre kapacitu 1000 kg/h

Frozen peas are vegetables ready for cooking quickly, requires no preparation, and most importantly is harvested at the top of their nutritional potential, thus including the most nutrients.

Ask for a price/Opýtajte sa na cenu

Catalogue/Katalóg linky

* Pictures are for illustration

Line consist from

Bulk receiving hopper with movable bottom/ lomený dopravník s pohyblivou násypkou

Bulk receiving hopper with movable bottom/ lomený dopravník s pohyblivou násypkou

Fresh peas put into a hopper, which is then transformed into the next phase lines. The hopper has an adjustable height along the axis of the conveyor. Belt speed is adjustable via frequency converter.

Information about the product:

Suitable for dry, frozen and fresh products Full washdown facility.

Design of the equipment:

- deep galvanized iron structure

- sides in stainless steel

- rotating fingers in ss. at carrot to accelerate product flow

- vari-speed motor-gear unit with electronic frequency converter for belt

- fix motor-gear-unit for rotating finger

| Power | 2,75 kW |

Dimensions:

| A | B | C |

| 6500 | 2000 | 2500 |

Belt conveyor/ Pásový dopravník

Belt conveyor/ Pásový dopravník

Material of construction AISI 304

belt- material suitable for food industry

As a transport medium is used a continuous belt which transports the material to a distance of about one hundred meters up to a rate of from about 0.1 to 0.6 m / s. Belt width can range from 10 cm to 3 m

Technical characteristic

| Power | 1,1 kW |

Dimenzions of equipment

| Belt lenght | 8900 |

| Belt widht | 600 |

Flighted belt elevator / "Dopravník husí krk"number of conveyors in line 3pcs / conveyors are identified by necessary belt width

Flighted belt elevator / "Dopravník husí krk"number of conveyors in line 3pcs / conveyors are identified by necessary belt width

the number of conveyor in line : 4psc

All stainless steel heavy duty conveyor fitted with slatted food quality linked feed belt with integral side guides and flights. Suitable for carrying all types of food products

.

Material stainless steel- AISI 304

Technical characteristic

| Power | 1,1 kW |

Dimensions

| Belt lenght | 5500 |

| Belt widht | 500 |

Drum prewasher/ drum pre-washing machine and washing machine/ predumývačka a umývačka/ bubnová umývačka

NUMBER OF WASHER IN LINE 3psc

Design of the equipment:

- frame and feet and drum in ss.

- drum has got special shape to increase the cleaning area

- vari speed motor-gear unit with electronic frequency converter

- infeed and discharge chutes

- three section drum, two different perforated and one without perforated

- waste removing conveyor belt

Dimensions

| Drum lenght | 2500mm |

| Drum diameter | 1000mm |

Technical characteristic

| Power | 2kW |

vibratory feeder/ vibračný podávač

Design of the equipment:

- frame and feet in deep galvanized iron

- non perforated vibrating trough in ss.

- vibrating trough mounted on springs

- ITALVIBRAS drive unit

- electronic brake for smooth off position

Dimensions

| Lenght of feeder | 1600 |

| Width of feeder | 600 |

Technical parameter

| Instaled power | 2x 0,55 kW |

fan separator

- stainless steel structure

- product feed and discharge chutes

- vertical waste separation

- rod-type screen

- waste discharge chutes

- powerful impeller

- frequency controller

Dimensions

| Lenght of separator | 1600 mm |

| Width | 800 mm |

Power

| Installed power | 4 kW |

DESTONER/ Rubber destonig belt/ cyklónový odkameňovač

DESTONER/ Rubber destonig belt/ cyklónový odkameňovač

Design of the equipment:

- frame and feet in ss.

- infeed hopper ss.

- food grade ribbed belt, for elimination of very light stones

- vari speed motor-gear unit with electric frequency converter

Power

| Installed power | 0,37kW |

Dimensions

| Lenght | 2200 |

| Widht | 800 |

inspection conveyor/ inšpekčný dopravník

inspection conveyor/ inšpekčný dopravník

Pieces in the line 2p

Iinspection conveyor is used for inspecting and sorting products in food, industry. The inspection conveyor is made of high quality stainless steel. The belt is made of PVC food. The belt is white in order to better control the product and classify

BLANCHER/ zariadenie na blanšírovanie

BLANCHER/ zariadenie na blanšírovanie

Blanching is rapid heating of fruit or vegetables, which stops the activation of enzymes, which causes deterioration in flavor, texture and nutrients. Blanching slows or completely stops the activity of enzymes that cause the vegetables lose flavor, color and texture.

Design of the equipment:

- all structure in ss.

- food grade modular belt, cleaning sprays under

- vari speed motor gear unit with frequency converter

- watering feeding system with centrifugal circulation pump

- direct steam injectors

- counter current cooling system with circulation pumps

- complete electrical control system

- to reach highest cooling efficiency need ice water for the last sector

provided by customer

Dimensions

| Lenght | 6500 |

| Widht | 700 |

Technical parameters

| Power | 10kW |

| Steam consumption | 400kg/h |

| Water consumption | 4 m3/h |

| Pressured air consumption | 10 Nm3/h |