DISPENSER, FILLING MACHINE

Filler (dispenser) is used for filling and dispensing creams, jams, fruit fillings, coatings, nectars, juice, mustard, gels, facial masks, waxes, adhesives, grease, sealers, mayonnaise, syrups, honey, butter, jelly, sauces , ketchup, paste, shampoo, soap, alcohol, chemicals, cosmetics, beverages, pastes and etc.

It can be also used optionally for filling of high-density products such as: potato salad, pastes, and etc

It is suitable for pumping cold and hot products.

The speed and performance of dosing can be adjusted. Filling accuracy is very high.

.Control of the bottles - if bottle occured, dispenser will automatically stop.

It can be used for different volumes, different products and packaging (cups, bottles, cups, ...).

It is made of stainless steel, so that we achieve the highest quality and hygiene. Based on the potentiometer reduces the loss can decline up to 0.5%.

Proccess

- Filling of the product

- Dosing of the product

Advantages/ Benefits

- Low noise

- Easy to clean

- Very low rotation speed

- Ease Installation

- High performance

- High reliability

- Extreme accuracy

- Universal uses

- Long life durability

- Setting of dosing

- Not dripping

- Adjustable dosing speed

- Adjustable filling speed

- High precision of filling

- Can function as a pump - dispenser

- Can draw also a substance , which contain pieces

- Low cost operation

- Suitable for sparse and dense products

- Suitable for cold and hot products

- Different capacity of hopper

- Suits the GMP

- High security

Principle:

Piston filling machine- may be powered pneumatic piston or hydraulic piston.

Piston filling machine- may be powered pneumatic piston or hydraulic piston.

Piston filling machine work on the principle thrust piston back into the bottle, the product is drawn from the supply tank to the hopper. Reverse valve then changes position so piston, which is placed downward, the product is removed from the space of piston into the container via a fill nozzle. The volume of the product is determined by the size of piston cylinder. This method is very accuratable. Piston filling machine can be with check valve or a rotary valve.

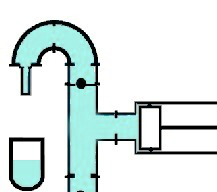

Check valve - piston filling machine works on the principle of non-return valve which only allows flow in one direction. The great advantage is that the check valve itself can draw product directly from a drum or other container. Check valve uses a system that opens and closes the throat.

Check valve - piston filling machine works on the principle of non-return valve which only allows flow in one direction. The great advantage is that the check valve itself can draw product directly from a drum or other container. Check valve uses a system that opens and closes the throat.

Rotating valves are used for dosing very dense substances (pasta, butter, cottage cheese, ...).

The rotary valve is connected between the container and hopper. The rotary valve features is a large throat for allowing the passage of the product particles. Delivery is supplied from the hopper and through the wide throat, the product does not infringe.

Piston filling machine can be used up to sparse to very dense products. Amount of the product is adjusted simply by adjusting the length of the piston stroke. Settings are done by rotating adjuster wheel by a small level.

The volume of discharged level is reduced due to the lifting height. When there is the extension of piston stroke greater delivery of product.occurs.

Steering

Manual control is used for simpler machines and technological equipment, which the technological process is complex and therefore do not require complicated programming. Simple operation using the ON / OFF button.

Types

Single head pistol filler

- Electric or pneumatic power with footswitch

- Stainless

- Various capacity of hopper

- Pneumatic controlled rotary valve or ball check valve

- Automation

2 head piston fillers

- Contains 2 heads

- Simple and lightweight design, which makes filler possible move easily to another location

- Used in the pharmaceutical, chemical and food industries

- Stainless

- Speed and volume adjustable

- High accuracy

4 head piston fillers

- low cost on 4 heads

- Connects two standard systems with two heads with prolonged nozzle

- Used in the pharmaceutical, chemical and food industries

- Stainless

- Speed and volume adjustable

Options

- Pistons made of stainless steel

- Heads: 2, 4, 6, 8, 10

- Inline / round dispenser

- Hopper with lid

- Jets

- Stirrer

- Heating

- Heated funnel

- Heated valves

- Teflon part

- Valves are also made of stainless steel, having high mechanical and corrosion resistance to wear

- Frequency converter

- Semi-automatic / automatic

- Automatic rotary table - increases the efficiency of implementation. Speed is adjustable.

We know the different types of dispensers and fillers:

- Piston - filling machine with 1, 2, 4, 6, 8, ... filling heads

- Piston - check valve al. rotary valve

- Metering Pumps

- Solids dispenser

- Rotary liquid filling machine

- Gravity systems

- Pressure filling machine

- Volumetric filling machine

- Filling device of type of product, for example. honey filling machine, filling tomato paste

Rotational liquid filling machine

Fully automatic rotary filling machine for liquids. Made of stainless steel. Centrifugal al. gear pump.

Dispensers of solid products

the auger/screw dispenser - for solids product and also medicines, spices, powder, milk powder, sugar, coffee, tea, seeds, granules etc.

- Easy to clean

- Simple design

- High speed

- High accuracy

Gravity systems This type ( same principle like hoppers) is installed above the filling head, where sre the solenoid valves for opening and closing. The volume is determined by the timer. Lower accuracy.

Volume filler - for fine powders - powder, flour. Auger filling machine - faster and easier

Pressure - Pressure filling machines are the most popular. They are economical, accurate, filling fluid level - equally to all cylinders. Automatic / semi-automatic Heads 2-14 (depending on the size of the bottle).

Honey filling machine is used to fill the honey. Honey filling machine is designed to meet the honey. High accuracy. Made of stainless steel. It is used in the food industry. Ensures comfortable and professional processing of honey. Filtering. Multifunction Device: dosage, creaming and drawing honey.

Technical parameters:

| Model | Normit D1 | Normit D2 | Normit D3 | Normit D4 |

| Pressure, Mpa | 0,4-0,6 | 0,4-0,6 | 0,4-0,6 | 0,4-0,6 |

| Speed ks/min | 8-14 | 10-15 | 20-25 | 16-28 |

| Filling range | 5-5000 | 5-5000 | 5-5000 | 5-5000 |

| Accurancy | -+1 | -+1 | -+1 | -+1 |

| Model | Normit D5 | Normit D6 | Normit D7 | Normit D8 |

| Pressure, Mpa | 0,4-0,6 | 0,4-0,6 | 0,4-0,6 | 0,4-0,6 |

| Speed ks/min | 20-30 | 40-60 | 60-100 | 100-200 |

| Filling range | 5-5000 | 5-5000 | 5-5000 | 5-5000 |

| Accurancy | -+1 | -+1 | -+1 | -+1 |

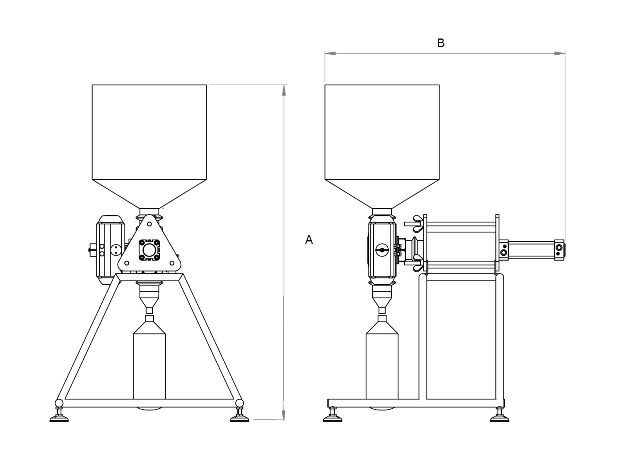

Dimensions

| Model | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 |

| A | 737 | 737 | 1016 | 1270 | 1422 | 1676 | 2000 | 2250 |

| B | 406 | 406 | 1219 | 1016 | 737 | 1016 | 900 | 1000 |