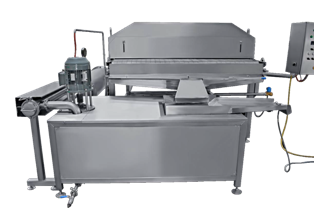

Industrial continuous fryer Pour Oil

The series of Industrial continuous fryers Pour Oil 2000/8500 is the current boom in the market of frying and roasting equipment.

The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.

Industrial frying equipment with low oil consumption

The Fryers from Pour Oil series are using the lowest oil volume in the system, which significantly reduces the manufacturer's costs associated with replacing and recycling waste oil. The high efficiency of oil reduction, its intense circulation, and constant filtration ensure an unbeatable quality of the fried product while retaining all its important properties.

The Fryers use a hot oil baking process and are ideal for frying meat, fish, vegetable and pasta products with a hard or fragile structure, wrapped or not wrapped.

Examples of use

- Chicken thighs

- Hamburgers

- Sliced rings of aubergine, zucchini

- Nuggets

- Croutons

- And others

Methods of frying on a continuous fryer

Pouring of hot oil provides results comparable to hot oil immersion and is effectively used for roasting large pieces of meat and fish products for which quality frying is necessary. The hot oil produces a film on all sides of each piece of product, its intense circulation between the product and the heating source ensures that a uniform set temperature is maintained throughout the frying surface. The oil film is also formed on the mesh conveyor under the product. Due to the minimum time of oil transition from the heat source to the product, the oil does not overheat.

High heat exchange indicators ensure the efficiency of roasting as if the product was constantly stirred in hot oil. At customer's request, it is possible to install a single or multiple product turn-over sections.

Always pure oil - a guarantee of a high-quality finished product

The whole volume of oil is subjected to continuous filtration in a continuous conveyor fryer. Fine parts of the product are continually removed using special multi-stage stainless steel filters. The operator visually determines the degree of contamination of the filter and the necessity of cleaning it. The filter is cleaned during operation of the device, while oil filtration continues with the second double filter.

The intense oil circulation between the heat exchanger and the product, as well as precise temperature control, prevent local overheating of the oil, which does not negatively affect the features of the product.

Special features of the construction for the stable operation of the Pour Oil continuous fryer at high temperatures

- The construction is characterized by high stability, robustness and also durability.

- The external drive is not subject to overheating which could cause deformation and leakage of gear oil.

- Easy-to-remove cover ensures thermal insulation and release of vapor and smoke through the ventilation system and built-in filters.

- A labyrinth seal is used to prevent fuel gas leakage.

- The safety of the operator is ensured by a reliable thermal insulation layer.

- The design dynamically compensates the thermal expansion of the metal.

Frying mesh

The conveyor nets are made of high-quality stainless steel, they are hygienic and easy to clean. Optionally, it is possible to install special "turbo brushes" for continuous mechanical mesh cleaning during frying. Continuous conveyor fryers Pour Oil are manufactured with electric, steam or gas heating system.

Video from the test:

In our facility we have laboratory machine -for test:/ test are for a fee

For more information on our continuous fryers, and for a free consultation, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.