Blancher - Thermoscrew NORMIT

Model: BLANCHER ThermoScrew

ThermoScrew Continuous screw blancher is a convenient and effective solution for high-performance industrial heat treatment of bulk and lump products, such as:

- Fruits and Vegetables

- Legumes

- Mushrooms

The continuous operation of the blancher ThermoScrew can significantly improve performance and reduce costs when moving from a batch production method.

Design:

The design of the blancher consists of a cylindrical cooking chamber, equipped with a heating jacket and an insulation layer. Inside the chamber there is a large diameter screw half immersed in the working vessel. A lifting sectional cover with additional insulation provides convenient access to the entire inner surface of the cooker.

How is it work:

The ThermoScrew blancher is designed for high performance and operates continuously. The product is distributed uniformly inside the cooking chamber through the feed conveyor and is moved by a screw to the discharge zone. For maximum efficiency of the blanching, the intensive hydrodynamic mixing principle is applied, whereby the product moves along the cooking chamber, rotating vigorously in the transverse plane. Intensive water circulation ensures uniform heating and its maximum heat transfer between the heat exchanger and the product, as well as ensuring that the product will not stick and is exposed the same heat treatment on all sides.

Features:

- Blancher - ThermoScrew is manufactured entirely of stainless steel AISI304 (other materials available on request).

- Depending on the needs of the customer, the equipment can be manufactured for steam, electric or gas heating.

- The special design of the discharging device ensures a uniform product discharge with no dead zones or sticking.

- Flexibility in configuration.

- Economical consumption of water and energy.

- Quick warm-up, the first batch of product is loaded into the heated to a pre-determined temperature water.

- Thanks to the constant intensive filtering, water stays clean longer. Effective two-stage forced filtration system is applied.

- The design of continuous blancher has a stable common base that ensures the reliability and durability of construction, even with large dimensions of the machine.

- Reinforced insulation protects operators.

Individual Design Engineering

Continuous screw blancher is designed and manufactured in accordance with the nature of the product, the required performance and customer requirements of the technological process.

Special design of feeding and unloading zones is possible. The ThermoScrew blancher is supplied with all necessary auxiliary equipment (feeding conveyors, cooling conveyors, excess water removing system etc)

Advantages:

- Suitable for a wide range of products, the possibility of a rapid change to a new product for the processing in the same machine.

- High performance and ease of use at the same time.

- The uniformity of heat treatment.

- Continuity process ensures consistent high quality of the finished product.

- Efficiency – the minimum possible water and energy consumption.

- Operator Safety – feeding and discharging of the product are carried out automatically, without operator intervention. No need for regular opening and closing the lid.

- High energy efficiency. Blancher is equipped with high-quality durable insulation. Product processing is carried out in a completely closed system with minimal heat loss.

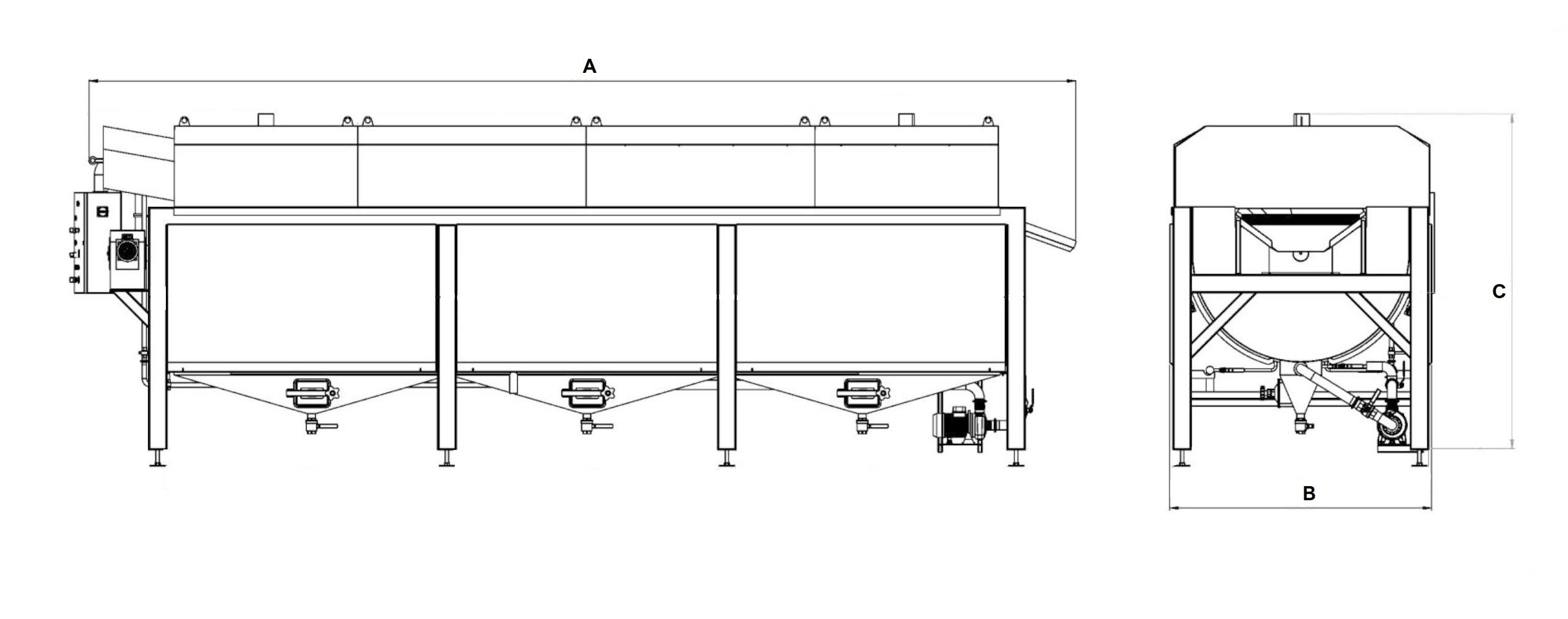

Dimensions:

|

Model: ThermoScrew |

1000 / 3000 |

1400 / 6000 |

|

Length, mm |

3 500 |

6 500 |

|

Width, mm |

1 200 |

1 969 |

|

Height, mm |

1 600 |

2 300 |