STONE FRUIT PROCESSING LINE

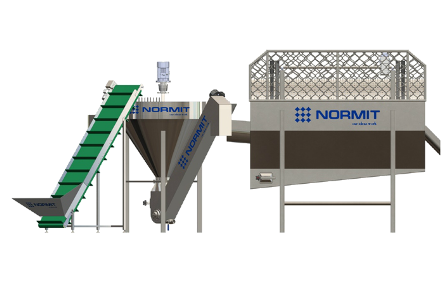

Stone fruit processing line consist of:

1. Bin tipping machine - for emptying products from plastic or wooden pallet boxes

SUITABLE BAGS

- large bags

- plastic bags

- boxes

- plastic boxes

- wooden pallet boxes

ADVANTAGES

- easy to use

- easy maintenance or cleaning

- amendable speed for tilting

- stainless steel design

- hydraulic drive

- manual operation

- suitable for boxes of different dimensions

- stainless steel design

2. Inspection conveyor/option sorting conveyor

The inspection conveyor is intended for sorting of legumes, peas, beans, corn, potato, tomato. The inspection conveyor is made of high-quality stainless steel. The belt is made of PVC. It is in white color, enabling easier controlling and sorting of the product.

Benefits:

- Easy maintenance

- Easy to wash and clean

- Rapid control

- High-quality material

- Adjustable belt speed

- Amendable legs

- Integrated lighting for enhanced vision

- Frequency converter

- Higher resistance

- Longer service life

- Manufactured to GMP standards

3. Fruit washing machine - brush washing equipment

Normit Brush is constructed to wash apples, cucumbers and other fruit and vegetables with the similar structure. It is intended primarily for cleaning fruit and vegetables that need to be preserved.

Advantages

- Completely constructed of stainless steel.

- Installed on pivoting wheels.

- Brushes constructed from non-toxic materials

- Separable brushes for simple washing

- Simple washing of the entire washing machine after using.

- Lid may be open.

4. Destoner/ pulper

Intended for destoning, stone washing and pulping

for making fruit puree.

5. Destoning machine for removing stone prior to further processes.

Benefits

- Hygienic

- Low water consumption thanks to recirculation, very hygienic design

- Pre-washing system

- Simple process management

- Long residence time for improved separation

- Simple to operate and maintain

6. Screw conveyor for stones - transport stones into the stone cleaner.

7. Stone cleaner - for cleaning stones after removing

8. Mash pump - for pulping destoned mass from de-stoner to pulper

9. Pulper - to achieve fruit puree

10. Self-cleaning filter - used for puree filtration after pulping, manual cleaning is not required

11.Tanks and vessel - intended for storing the puree and heat treatment.

Options:

- Cooling jacket.

- Connection for mixer/agitator.

12. Open tanks/ Mixture for cleaning supplements

13. Pasteurizer - suitable for juice pasteurization

14. De-aerator - is used for the removal of air bubbles from the purée, which occurs in pupler during preparation.

15.Homogenizer - making the product more stable, reduced it size

For more information about this product, please contact our sales department at This email address is being protected from spambots. You need JavaScript enabled to view it.