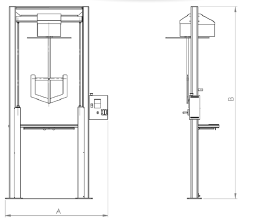

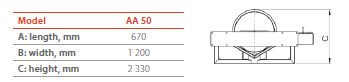

Barrel mixer | Drum mixer AA 50

The unit is ideal for mixing and liquidising directly in the pot or pan for making cake filling and creams, mayonnaise and other similar product. Designed for frequent use with large production.

For more informations please contact sales department: This email address is being protected from spambots. You need JavaScript enabled to view it.

Processes

- Constant stirring in containers

- Homogenization

- Pumping

- Dissolving

- Deagglomerating

- Dispersing

- Emulsifying

The Disperser is designed to break out the dry ingredients (pigments, dyes and other materials) in liquid to obtain suspensions, emulsions and pastes with a high degree of dispersion. The blades transmit high shear forces to the material being dissolved, cracking them apart. The dissolver distributes the liquid to solids. High Speed Dispersers are perfect for viscous dispersions.

The system allows three processes:

- immersing of solids in a liquid

- mechanical grinding and separation of particle clusters

- the stabilization of newly formed small cells and preventing their re-flocculation (aggregation).

Process is important for the formation of a homogeneous mixture of a single structure with a stable

biological activity.

Principle:

To work with this equipment, operator needs to move it upwards and place the vessel below the dissolver. The mixing tool is placed on the frame of the equipment. The stirring is performed in a closed equipment. Motor with gearbox is located centrally. The impeller has an adjustable height. Lifting can be pneumatic, hydraulic or electromechanical.

Controlling:

Manual controling was constructed for more simple machinery, where the technological method isnt complex and as a result dont require complex programming. Easy operation with the ON / OFF button.

Benefits:

- Versatile - suitable for a wide range of products.

- Universal device .

- Easy to use, easy to cleaning.

- Stainless steel AISI 304, AISI 316.

- The unit is composed designed for batch size from 10-500 L or according the customers needs.

- The speed is repeatedly amendable.

- Consistent power in the top range of speed plus with speed control, thus the disperser is secured against overloading.

Options:

- Design to work with vacuum

- Monitoring temperature

- The containers with different size and design, can be provided with jackets for heating or cooling.