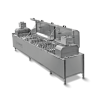

Commercial continuous fryer NORMIT for breaded products

Commercial continuous fryer - excellent in effectiveness and environmentally

This continuous fryer is the latest phenomenon in the field of food processing machinery. The construction of this continuous fryer, invented by experts with the latest, factual knowledge in production of continuous fryers, guarantees superiority in effectiveness and environmental friendliness.

Powerful exceptional frying of many different breaded food products.

Spraying products with hot oil guarantees heat transmission compared to the process of immersing food in hot oil. It is ideal for frying various food, such as big portions of meat or fish products, for which higher quality frying is compulsory.

Continuous fryer - SUITABLE PRODUCTS:

- Chicken nuggets

- Chicken with bones

- Meat patty

- Tempura shrimp

- Chicken breasts

- Meatballs

- Egg rolls

- Coated veggies

Industrial fryer ShowerFry works with an approach of spraying hot oil, that is perfect for frying meat, fish, vegetables or dough products, snacks with solid or delicate structure, breaded or not breaded.

Frying equipment with minimum percentage of oil, reducing costs, while maintaining excellent quality of fried food

The Normit continuous fryer uses the minimum amount of oil in the entire process to the performace, so substantially decreasing expenses for the removing and dumping of waste oil. A large oil turnover, its intense circulation plus steady filtrating, ensures an excellent quality of fried food, plus conserving of its nutritious characteristics.

Frying equipment with constantly clean oil, an assurance of a higher quality final products

The whole amount of oil in the ShowerFry continual fryer machine goes through consistent filtrating. Tiny food pieces are constantly eliminated thanks to the certain multi-level stainless steel filters, and the staff visibly decides the level of contaminating and the demand for filter washing. Filter washing is achieved while operating of the machinery when oil is being filtered thanks to the second filters.

To receive a price quote or for further info, send us an email to This email address is being protected from spambots. You need JavaScript enabled to view it.

Other equipment ideal for batter breading

AUTOMATIC BATTER BREADING EQUIPMENT

We offer two types of automatic batter breading machines. Compact or Mini version. They are constructed for batter breading prducts like meatballs, burgers, soy, veggie burgers, croquettes, vegetable and many others. If you have a smaller catering firm or need a large manufacturing capacity, we are capable to provide the right solution.

FEATURES

- width 150 mm

- Speed - 10 m/min (compact) or speed changing from 9 - 15 m/min (mini)

- Producing - 2000 units/h (compact) or 2000 to 3000 units/h (mini)

- Motor power: 180 watts (compact) 250 watts (mini)

- Tabletop device (table available)

- Possible to deassemble it for easier washing

- Simple care

- Low price

- Weight: 55 kg (compact) or 110 kg (mini)

- Dimensions of the equipment if assembled: 1000 x 485 x 400 mm (compact) or 1440 x 500 x 1100 mm (mini)

- Dimensions of the equipment when packed: 1450 x 700 x 800 mm (mini)

- Inverter for clearing bread (mini)

- Blower for surplus liquid (mini)

- Units fall in the belt or go down the ramp to eliminate surplus bread (mini)

- Support for the tray at the end (mini)

- Installed on four legs with stainless steel wheels (mini)

BREASTS SLICING EQUIPMENT

Tabletop compact chicken breasts slicing equipment. It manufactures up to 300 kg/h. Loading and unloading of the product is done on one side of the equipment. Suitable for smaller catering firms, butcher or small capacity meat manufacturing plant. Made for the meat sector.

Tabletop compact chicken breasts slicing equipment. It manufactures up to 300 kg/h. Loading and unloading of the product is done on one side of the equipment. Suitable for smaller catering firms, butcher or small capacity meat manufacturing plant. Made for the meat sector.

FEATURES

- Table top compact equipment

- Makes up to 300 kg/h

- Loading and unloading from the front

- Slices four or five cuts per breast

- Operating security mechanism

- Dimensions - 530 x 430 x 340 mm

- Weight - 60 kilograms

- Noise - acoustic pressure under 70dB (A)

- Manufactured in stainless steel

- Very simple operation

To receive further info on any of these machines, email us at This email address is being protected from spambots. You need JavaScript enabled to view it.

Also, we have a smaller version of fryer