CIP system

CIP

The CIP (Clean-in-Place) is designed for interior cleaning of tanks, pipes and industrial equipment in production lines without dismantling. Originally CIP disinfection used mainly in factories, in places where there were increased demands for wholesome products (dairy, pharmaceutical companiens), but with the development of technologies and companies in various industries using CIP system as technological equipment.

CIP systems significantly improve the economic performance of the

CIP systems significantly improve the economic performance of the

company due to its advantages such as:

Significant reduction of the period of sanitation cleaning equipment, reducing downtime;

Significant reduction of the period of sanitation cleaning equipment, reducing downtime;

- Economical use of maintenance;

- CIP systems use software for effective cost of detergents;

- Improved sanitation facilities with hand washing. The absence of human factor provides a sustained high rate care about the finished product

NORMIT CIP cleaning systems meet stringent European standards for quality and reliability, while being cost efficient solution than implement modern washing facilities.

Benefits of CIP disinfection

- high product quality ensures long-term trouble-free operation, which is confirmed by the ECP.

- In the manufacturing process used materials and components only from leading European manufacturers;

- Reasonable price of the equipment, possible to make a device according to the customer;

- High efficiency;

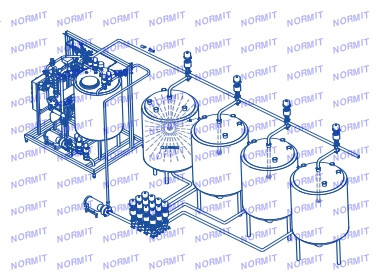

- Can be used for cleaning various equipment - tanks, pipes, dryers, pasteurizers ...

- Easy maintenance

- Precise preparation of cleaning solution and maintain the desired temperature;

- Ability to work quickly with other detergents or other types of equipment;

- Any degree of automation - from initial integration into the production system of the company;

- Can be fitted with additional equipment (stands cleaning solutions, storage tanks acid, soda and water, neutralization of waste water ...)

- The possibility of making the CIP cleaning of the EX version is ATEX certified (in case it is used for petrol or organic solvents);CIP cleaning can be provided with a hot air pipe.

Each individual station CIP is based on information from the customer:

- Type of device to be purified CIP system (tank, the drying unit ...)

- Technical parameters of the device (flow rate, volume, etc.)

- The number of rinses device for determining the required number of circuits CIP disinfection

- The length and diameter of the pipe

- The cleaning program that will provide the highest quality at the lowest cost of time, energy and detergent

Kind washing facilities NORMIT CIP differ in design and functional features of the model:

- One-, two-, three- or four capacitive CIP cleaning with a standard volume of 100 to 5000 liters.

- Tank capacity is determined by the technical characteristics of the device. To request the CIP system produced with any volume of containers;

- Model of 8 units is standard.

- Stationary or mobile version

Automation:

Our company offers CIP disinfection with different levels of automation, depending on the needs of the customer - from the hand-washing, to fully automated solutions, including control over dispensing detergent (with dosing system). Maintains optimum concentration of the cleaning solution in the working tank, controlled detergent concentration. Time management, cleaning process, temperature, and archiving of all data, etc.

Automatic selection system:

CIP system allows you to control the system, including through the Internet or via LAN.

When choosing the level of automation for CIP cleaning is important to understand that when you buy a more expensive system with a high level of automation, you can invest money in efficacy and safety equipment, thereby reducing operating costs in the future.

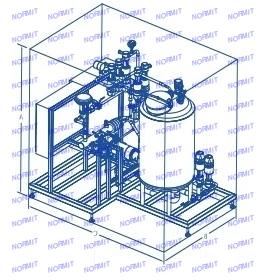

One and two capacitive CIP systems NORMIT serve small businesses

Overall dimensions

Height 2440 mm

Width 1830 mm

Length 2740mm

Weight 1900 kg

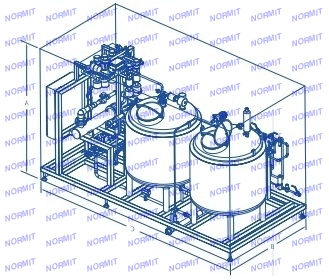

Overakk dimensions

Height 2440 mm

Width 1830 mm

Length 3960 mm

Weight 3100 kg

standard single-circuit CIP system NORMIT composed of four tanks