Continuous deep fat fryer ODF 50

Model: ODF 50

The continuous conveyor deep-fat fryer is a reliable and universal solution for high-performance frying of a wide range of products by immersing them in hot oil.

Easy to use and maintain, minimum consumption of oil and continuous filtering of it, careful processing of products — all these features make fryer an ideal solution for industrial frying.

The continuous fryers use the method of immersing the product into oil at an adjustable depth and are ideal for frying meat, fish and vegetable products, as well as products made from dough, snacks, products with a hard or brittle structure, and with or without breading.

Example applications:

French fries

Chicken legs

Hamburgers

Meat dumplings

Nuts and seeds

Eggplant and zucchini rings

Dough products

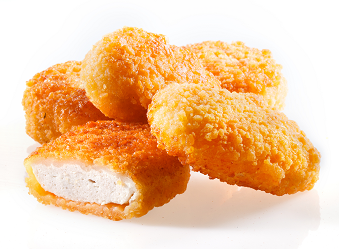

Nuggets

Croutons

Frying method

In the series of continuous fryers, products are fried by immersion in hot oil and by moving across the frying bath on a single conveyor belt. The distinctive feature of conveyor fryers is the ability to easily adjust the level at which the conveyor belt is immersed into oil. The precision of adjustment is 0.1 mm, which allows frying products of different height in the same deep fryer. In the basic version, the depth of immersion is adjustable within the range of 0–150 mm. The product moving on the conveyor belt does not float and is completely immersed in the oil up to the set degree. Adjusting the immersion depth is done smoothly and it takes just a few minutes, which allows you to switch to frying other types of products without wasting time.

Heating, circulation and filtering of oil

Hot oil circulates intensely between the heating system and the product, and the oil

flows in the direction towards the product. The oil yields its thermal energy to the product very quickly, thus ensuring a similar thermal load as the product would be subjected to if it were constantly being stirred in hot oil. The oil is filtered uninterruptedly with the aid of stainless steel filters with replaceable stainless

cartridges. The fryers can feature an electric heating.system.

Advantages

Universal application, quick switching to frying of new types of products, possibility of using special frying modes.

Easy cleaning and maintenance, conveyor that can be conveniently disassembled guarantees easy access to all internal areas of the fryer.

Minimal amount of oil in the system, uninterrupted filtering of oil, high oil replacement coefficient – in most cases there is no need to replace the oil due to rancidity, and only fresh oil has to be added into the system.

High efficiency and production capacity within a small surface area.

Manufactured to a high standard of quality using European-made materials and components.

Possibility of supplying additional modules for loading and unloading of the product, subsequent cooling of it and removal of excessive oil.

Dimensions:

A: lenght, mm 3 100

B: width, mm 1 250

C: height, mm 1 850