Vacuum mixer homogenizer VMG / Make mayonnaise

Vacuum homogenizer VMG has been developed for use in the food, pharmaceutical and cosmetic industry for vacuum emulsifying products: mayonnaise, ointments, gels, pastes, creams, shampoos and the like.

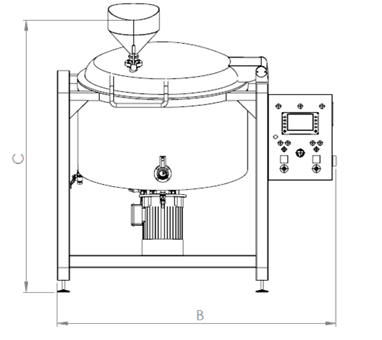

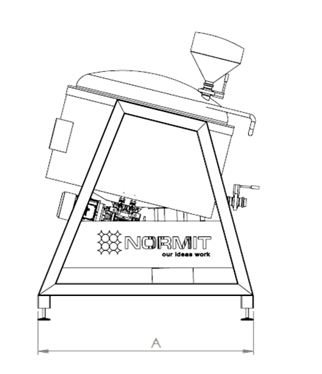

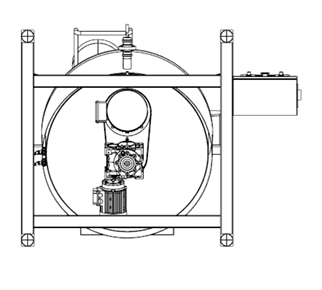

Vacuum homogenizer VMG is used in food, chemical, pharmaceutical and cosmetic industry for the production of liquid, viscous and pasty products. It is manufactured according to GMP standards and the highest standards of hygiene, therefore suitable for the production of medicines and food. The base has a triple-jacketed insulated container with electric or steam heating.

The hopper with a valve placed on the lid of the container is used for adding the product into the container. The high-performance homogenizer or the specially shaped agitator provide for wide circulation, soft mixing and homogenization of the product, and also an effective heat transfer between the vessel wall and the product.

VACUUM MIXER HOMOGENIZER - BENEFITS

- The working volume of the homogenizer 15 to 80% of the total

- Suitable for dense products

- The high quality of the processed product and long durability

- High batch reproducibility

-

Effective mixing and homogenizationHigh hygieneHighly reliable design, long lifeFlexibility with interchangeable toolLow operating costs

VACUUM MIXING MACHINE - USAGE

- Mayonnaise,

- Ketchup

- Sauces,

- Dressings

- Desserts, spreads

- Gels

- Creams

- Shampoo

MAKE MAYONNAISE - BASIC EQUIPMENT

- Material design AISI 304, AISI 316 on request, AISI316L, AISI316 Ti and other

- Construction with tilt with fixed position

- Frame stirrer

- The bottom homogenizer

- Frequency inverter for infinitely variable speed agitator

- Special seals

- Version for emulsification under vacuum

- Vacuum unit

- Hopper with the valve for fast replenishment of components

- Control box with button control

- Electric or steam heating

- The ball valve to drain the product

CREAM MACHINE - OPTION

- The possibility of producing the desired pressure

- Various types of mixer

- For measuring, weighing - components can be installed - flow meters, level strain gauge weighing system

- Sampling equipment without interrupting the process

- Electric drive for valve hopper outlet for the product

- CIP fixed or rotating head

- PLC for automatic control of the process

- Equipment for explosive environments ATEX

For more information, contact our sales department at This email address is being protected from spambots. You need JavaScript enabled to view it.